the Top Pyshma (Sverdlovsk oblast)

JSC "Uralelectromed" (metallurgical complex of UMMC) has cut almost a third of the duration of the cleaning and repair of electrolysis baths in the copper tankhouse (TSEM) running on unsupported technology. This result was achieved by pre-SKD circulation pipes and the use of modern harvesting machines. The event is made in the framework of the development of the business system of the company.

- introduction of the new scheme will reduce the operating time and other costs, which occur during execution of these works, improve equipment utilization and overall efficiency of the shop, - said the head of the copper electrolysis plant Sergey Gorelyshev.

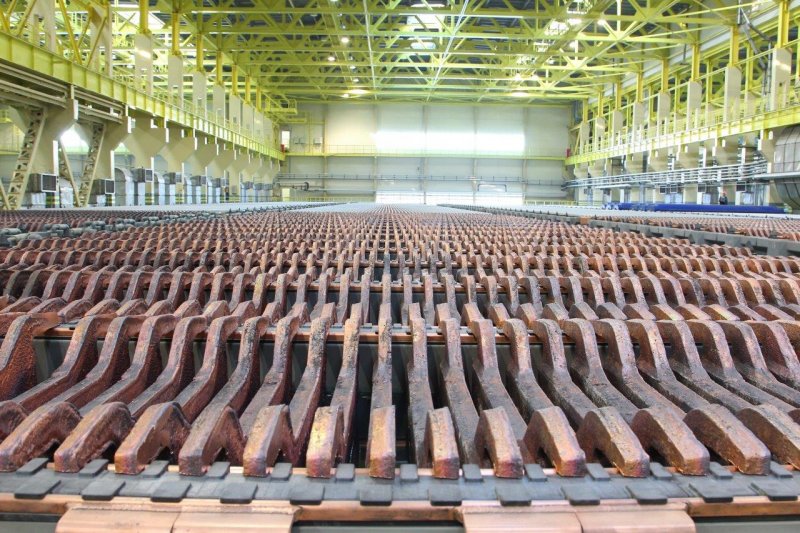

As explained in TSEM, polymer-concrete bath should be periodically cleaned of sludge generated in the process of circulation of electrolyte to carry out an audit of valves, replacement of the circulation pipes and the repair of baths. To optimize this long and tedious process, proposed a new scheme of work.

First comprehensive SKD Assembly of the new ventilation pipe (installed instead of the exhaust) – they are glued between themselves and going in the pipe layout with diaphragm valves. Then from the series consisting of 28 tubs, a fused electrolyte, removing the exhaust pipes, the walls of the baths are cleaned from the sediment using high-pressure apparatus KARCHER. The set of activities is completed with the installation of pre-assembled pipes and restoring the bath surface repair compositions.

as a result if before the cleaning and repair of bath required at least a week, now the process takes just over four hours. According to the calculations, a simple series of baths will be reduced by 30% or from 60 to 42 days a year.

Note that the new method of cleaning and fixing baths used for the first time on the first stage of the unsupported branch of the copper electrolysis plant. To select the best option was studied and analyzed the experience of other companies, including foreign ones. Just for the current year nine scheduled cleanings with a comprehensive revision of valves, replacement of pipes and restoration of the surface of the bath. At the moment, five series of baths is already cleaned from the sediment.