The Universities of Swansea, Sheffield and Warwick, as well as metallurgical companies will take part in the survey. The main objects of study will be: various energy sources, techniques for capturing emissions and the development of new products. A related goal of the project is to create additional jobs.

The country has pledged to reduce its carbon dioxide emissions by 80% compared to 1990, but so far this figure has been reduced by only 19% (at the Port Talbot smelters).

At the same time, £ 10 mil. Received through investment from the Engineering and Physical Sciences Scientific Council, the Wales Department of Education and the Steel Mills.

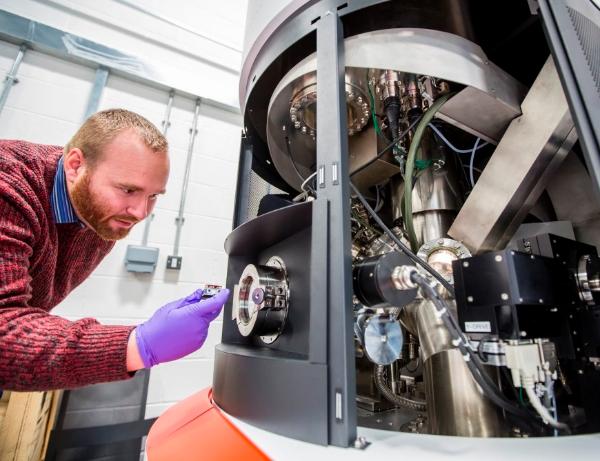

The latest technologies (special sensors, laser tempering) are designed to solve the problem by 2040, giving the world durable steel that is produced with minimal damage to the environment.

Along with capturing carbon - and reusing it - large steel mills have the potential to use scrap metal more efficiently and turn it into ideal sites for recycling household waste for energy.

Researchers are also focusing on the development of "smart " steel processing. This improves the way we manage the complex data and measurements used to make various types of steel products, including the use of sensors and laser technology, to improve efficiency and help manufacturers.

UK Steel CEO Gareth Stace said it is “a vital piece of the puzzle that will help us to realize our vision of a cutting-edge, dynamic and sustainable steel industry in the UK.

Professor Mark Reinforth from the University of Sheffield added: “Steel is a fundamental building block for every aspect of society. The development of higher performance steels with a reduced carbon footprint during production is the key to reducing CO 2 emissions. ”