At the Uralkabel plant (part of the Cable Alliance Holding, which unites the cable assets of UMMC), extrusion equipment in shop No. 22 was modernized. On the RN-K line, a second extruder is installed, designed for sheathing on insulated conductors. Its cost exceeds 280 thousand euros.

Previously, when one extruder was operating, the insulated core had to be driven through the line twice: first, an inner sheath was applied to ensure reduced smoke emission, and then an outer one was responsible for reduced flammability. Between operations it was required to stop the equipment to change the tool and refill materials.

Now the operations for the imposition of casings will go one after another, without interruption, which will double the speed of the production process at this stage. Accordingly, the lead time will be shortened and the production of cables for the oil, railroad and other key industries will increase.

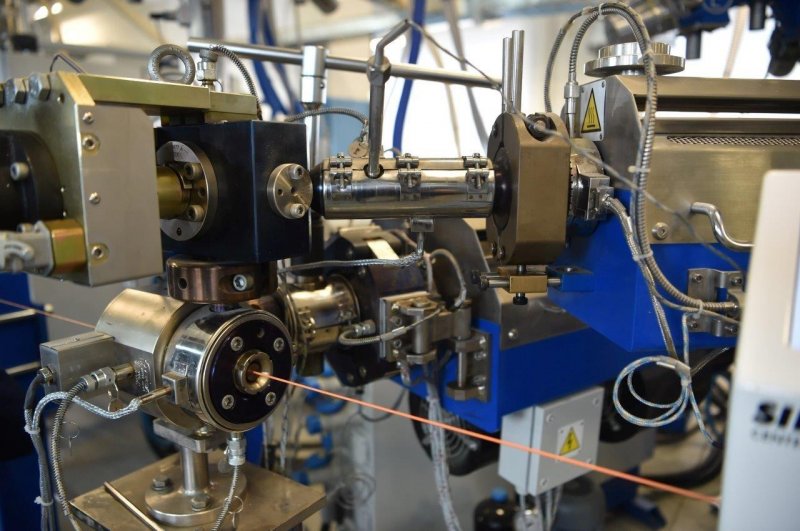

The new extruder can coat the conductor with plastic compounds, block copolymers, and halogen-free compounds. Under the influence of high temperatures (about 200 ° C), solid materials are melted and passed through a special forming tool that sets the parameters of the shell. Its thickness can vary from 0.5 to 2 mm, and its diameter is from 9 to 34 mm.

“We are constantly working to optimize the production process. This allows you to maintain a high level of cable quality and reduce its cost, which is critical in a highly competitive environment. Compliance with technological regulations is strictly controlled at all production stages: from wire drawing to sheathing, since even the slightest deviation from clearly calculated parameters is unacceptable when creating high-quality products, "said Evgeny Sukhodoev, Director of Uralcable.

It should be noted that over the past 9 months of this year, Uralkabel processed 5.8 thousand tons of copper wire rod and 284 tons of aluminum. The largest share in the product structure is occupied by auto pipelines, of which about 88 thousand km were produced - practically at the level of the same period last year. Also, a significant volume is accounted for by products for rolling stock. Aviation pipelines demonstrate significant dynamics this year.