Revda (Sverdlovsk Region)

Sredneuralsky Copper Smelter OJSC (an enterprise of the UMMC metallurgical complex) will spend about 1 million rubles for the construction of a drying chamber in a mechanical repair shop.

New construction is planned at the foundry site of the RMC, where a site for the preparation of molding sands was allocated during the technical re-equipment. Currently, preparatory work is underway, the acquisition of the necessary materials.

The new drying chamber is a room made of refractory materials with a volume of 20 m 3 . It will be equipped with heating devices, instrumentation and control systems. There is a rail track for the trolley, on which the mold will roll into the dryer and roll out of it. The project was developed by the design and engineering department of SUMZ.

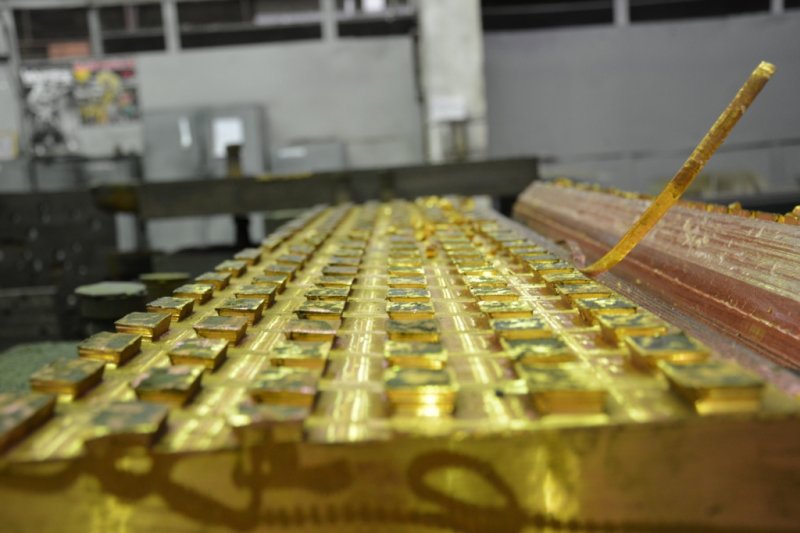

The drying chamber will allow to supply ready-made molds and cores for casting from the molding section to the foundry redistribution. But the most important thing is that three centrifugal casting machines will be installed in place of the old "dryer". Two of them are brand new and one is operational.

The above activities will help share traffic flows, to increase the production capacity of the non-ferrous casting section for the production of bronze and brass bushings.