Design of diesel generator sets (DGS) is a multi-stage process that requires a thorough analysis of technical and operational parameters. The main design stages include equipment selection, installation diagram development, calculation of fuel supply and cooling systems, connection to electrical and automatic control systems, as well as comprehensive testing and startup. Design of diesel generator sets (DGS) and diesel power plants (DES) at https://ukrstp.com/ru/razdely-proektirovaniya/elektrotehnicheskie-resheniya/proektirovanie-dizel-generatornyh-ustanovok/ is included in the range of services provided by the company “PI “UKRSPETSTUNNELPROEKT” ".

The main design stages include:

1. Selection of equipment

At this stage, a generator is selected taking into account the power and expected load. Specialists analyze the site's needs and determine the type of equipment (engine, generator, fuel tanks, control systems) to ensure efficiency under peak and continuous loads. The fuel (diesel, biodiesel), operating conditions and type of generator - backup or main are also taken into account.

2. Design of fuel supply and cooling systems

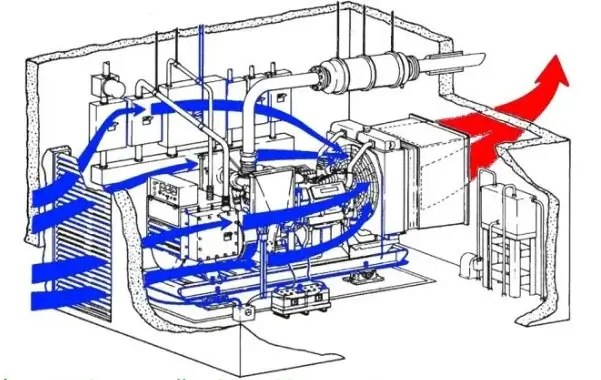

For stable operation of diesel generator sets, reliable fuel supply and cooling systems are required. Fuel tanks are designed for the required volume, taking into account the autonomous operating time of the installation. The cooling system ensures optimal operating temperature, and its parameters depend on the power of the generator and the external temperature.

At the design stage of electrical connections, the parameters for connecting the generator to the facility are determined. It is important to calculate the parameters of protective equipment, automatic switches and emergency transfer circuit (ATS).

4. Development of a control system

The control system is a key part of the diesel generator set, providing control over the operating parameters of the generator. Modern diesel generator sets are equipped with automated panels that allow remote monitoring and control of equipment. At this stage, the need for protection against overloads is established and emergency shutdown scenarios are thought through.

5. Installation work

Installation of a diesel generator set includes installation of a generator, fuel tanks, ventilation and cooling systems. At the site, the equipment must be installed in a room with good ventilation and sound insulation. At the same time, all connection schemes and vibration protection are thought through.

6. Testing and startup

Starting the installation involves testing all operating modes, calibrating systems and tuning to optimal operating parameters. After installing and connecting all systems, the generator is tested. It is important to test operation at idle, under load and at peak load. This ensures that the installation can operate stably and provides the specified parameters.

Each stage of the design of “UKRSPETSTUNNELPROEKT” provides a qualified approach, especially for complex facilities with high requirements for backup power supply, more details at https://ukrstp.com/. Competent selection of equipment and competent calculation of all systems guarantee stable and economical operation of the diesel generator set.