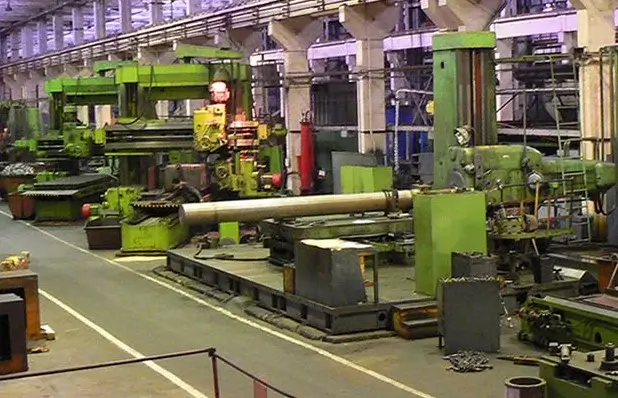

CNC machines are technically complex devices that periodically fail and require repair. This is a complex process that requires high qualifications and experience of specialists. Repair of CNC machine tools can include fault diagnosis, replacement or repair of worn or damaged parts, adjustment and calibration of control systems and drives, as well as testing and checking the performance of the machine after repair.

The repair of CNC machines must be carried out in accordance with the technical documentation and quality standards. Therefore, if you find a malfunction in the operation of the CNC machine, you can contact the First Amper company: https://www.pvamper.ru/promyshlennoe-oborudovanie/remont-stankov-chpu. There are specialists who have everything necessary for a quality repair of this equipment.

Causes of breakdowns

The causes of breakdowns of CNC machines can be very different:

p>

Incorrect software operation. Such a breakdown can be caused by errors in the program code, incompatibility with equipment, power or communication failures, as well as viruses or hacking. To eliminate such malfunctions, it is necessary to check and correct the program:

Overloading the device. This failure can occur when the permissible speed, power, load or temperature parameters are exceeded. Overloading can lead to overheating, wear or damage to components: spindle, bearings, drives, sensors, etc.

Failure to comply with operating standards. This malfunction may be due to the wrong choice of tool, workpiece, cutting fluid or process. Failure to comply with operating standards leads to low quality processing, damage to parts or tools, as well as to emergency situations.

Wear of components. This is a natural process that occurs over time during the operation of the machine. The wear of components can lead to a deterioration in the accuracy and quality of processing, as well as to machine breakdown.

The main types of breakdowns

The breakdowns of CNC machines can relate to electronics, mechanics or auxiliary parts. In the first case, the controller, inverter, spindle, wires or firmware may be faulty. Electronics failures manifest themselves in the form of program malfunctions, displacement or shocks along the axis, overheating or short circuits. To determine them, a test or logical diagnostic method is used. Mechanical failures manifest themselves in the form of a deterioration in the accuracy and quality of processing, vibration or noise of the device, play or jamming along the axis. To determine them, a practical or logical diagnostic method is used.

As for breakdowns of auxiliary parts, they manifest themselves in the form of accumulation of water or dirt in the collet or spindle nut, overheating of the tool, etc. Determining them will require a practical or test method.