A shot blasting chamber is a special room in which high-speed processing of large metal structures takes place against corrosion, scale, irregularities using shot throwers. This equipment (in common people "shot blasting ") is one of the most effective ways of cleaning material.

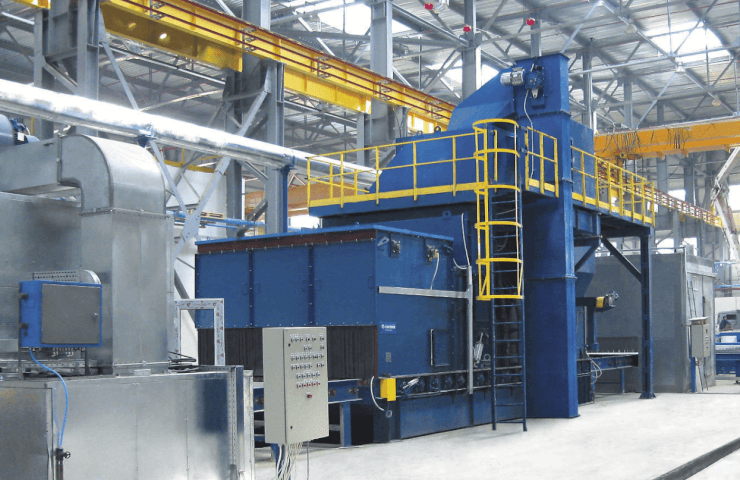

In the treatment plant, ventilation systems are installed to collect and clean the abrasive. Shotblasting chambers https://tweko.com.ua/products/drobestrujnaja-kamera / are installed in workshops to protect people, machines and the environment from dust and other emissions as a result of cleaning metal structures. The camera can be controlled by the operator, as well as - without the coordination of people, in this case, automatic installation is used.

Application and use

The method with the use of shot blasting chambers consists in processing an iron plane with a strong pressure of compressed air mixed with grains of abrasive materials. Previously, quartz and silicate sand was used as an abrasive. Nowadays, for high-quality cleaning of large-sized metal structures at enterprises, a shot-blasting chamber is used, in which the metal is cleaned from any dirt, old paint, chips, rust, allowing to achieve a smooth surface.

In the shot blasting chamber, you can clean both small and large items, such as: metal parts of ships, railway cars, containers. A shot blaster is used to clean the surface for further work. After complete cleaning and degreasing, the metal is completely ready for a new painting and its further use.

How it works

Cleaning of iron structures in a shot blasting chamber is carried out by the interaction of whole or chipped shot on the plane of the object. Under high pressure, the blast machine releases a jet of compressed air to a certain side to create a protective layer. The size of the fractions varies depending on the task.

The metal product moves inside the installation on a motor transport cart through a roller shutter entrance, which is tightly closed. Cleaning begins with the use of a shot blasting machine, in which the abrasive enters the compartment under high pressure. The automatic floor construction collects the abraded particles in a specific hopper. From where the waste and residues of materials are thrown into a separator, in which the shot is purified from garbage. The ventilation structure guarantees effective dust removal from the room. The camera is equipped with a mechanical board with a number of sensors. This is necessary to check the operation of the entire system, which notifies in the event of a breakdown.

The Benefits of Shot Blasting

The shot blasting method has a number of competitive advantages:

- The use of iron and cast iron shot hardens the surface.

- Ability to create a rough surface.

- High performance.

- Ability to clean large items.

- Successful cleaning of metals from corrosion, chips, paint.

- Ability to create a robotic process.

With the help of industrial innovations, work productivity is enhanced. It is possible to process large metal structures at a fast pace without unnecessary efforts. The main thing is to choose exactly the abrasive substances. When its density is lower than that of the treated plane, the particles will crack.

Blast chamber includes:

- Body and gate

The body is made of a metal skeleton and soundproofing. Inside the walls are covered with special insulating material. The equipment case can be dead-end or through-passage. Swing or lifting gates are used in shot blasting chambers.

- Ventilation

Since abrasive blasting generates a lot of dust, a ventilation unit is needed to clean the air inside. The characteristics of the treatment structure are selected based on the scale of the room.

- Abrasive system

Reusable abrasives, for reuse need to be cleaned of debris and small elements, this will require a bucket elevator. To improve the operation of the chamber, specific production means for collecting waste are used. Scraper floors are most suitable.

- Blast machine

When choosing compressor equipment, it is necessary to provide that the compressed air has different characteristics.

- Camera control

The blast chamber is controlled by the main control panel, possibly using keys and special indicators, as well as using the operator panel.

- Transportation site

Various methods are used to deliver the cleaned metal structures to the chamber: from a workshop crane to manual movement of small elements. The most famous