Verkhnyaya Pyshma (Sverdlovsk Region)

Uralelectromed JSC (an enterprise of the UMMC metallurgical complex) produced 400 thousand tons of copper cathodes based on the results of production activities in 2018, which amounted to 105.8% to the level of 2017 ... The enterprise has achieved this result for the first time in 85 years of its operation.

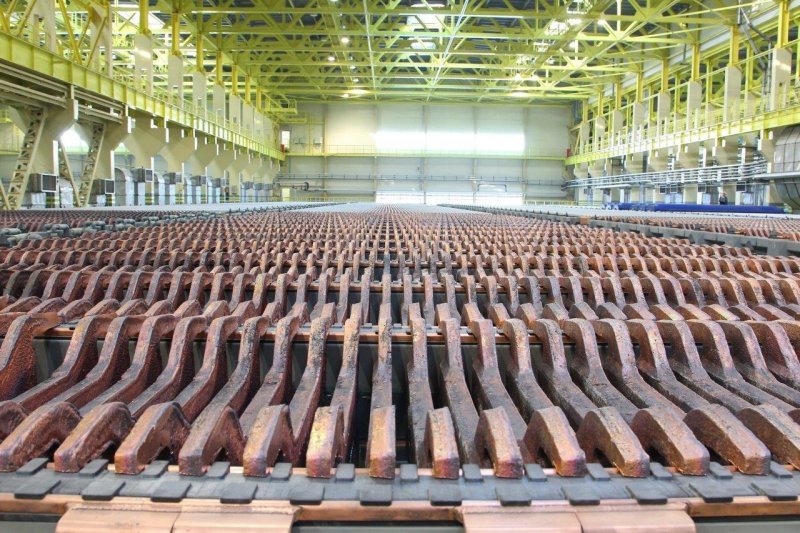

According to the chief engineer of JSC Uralelectromed, Alexey Korolev, this is primarily due to the commissioning in 2018 of the second stage of the copper electrolysis workshop, which operates on baseless technology.

- The design and equipment of the second stage of the new workshop was carried out taking into account the latest achievements and new technologies for copper electrorefining. In particular, a new generation cathode stripping machine, equipped with six German-made robots, was installed in the shop, he noted.

The use of robotic technology allowed to increase the productivity of cathode stripping operations by 40% in comparison with the cathode stripping machine operating on the first The cathode stripping machine performs the following operations: cathode washing, stripping, sampling to determine the chemical composition, bundling with a steel strap.

In addition, in 2018 the enterprise increased the output of copper wire rod to 170 thousand tons, which is 13% more than in 2017. Last year, the enterprise exceeded its plans for the production of copper sulfate - 108% to the level of 2017, nickel sulfate (+ 17%), tellurium (+ 4%).