The situation with the withdrawal of Western companies from the Russian market may cause concern, but in fact it opens up new opportunities for domestic production. In particular, the production of plastic products from plastic sheets (HDPE, PVD, HIPS, ABS, polystyrene) can be very popular on the market. And we, as a manufacturer of plastic sheets (HDPE sheets, LDPE sheets, HIPS sheets, ABS sheets), see a gradual increase in demand for our products.

Our market is structured as follows:

- Processing of petroleum products and obtaining raw materials for the production of sheet plastic;

- Production of sheet plastic of the required color, size, texture from granulated raw materials - the PromPlast plant does just that;

- Production using vacuum molding finished molded products is a niche that we would like to offer you in this article.

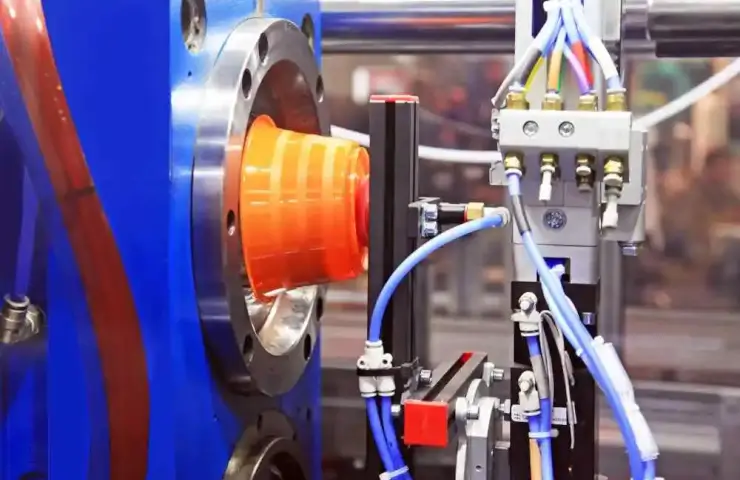

Vacuum forming is one of the most common methods for the production of plastic products. With this technology, you can produce various types of products, including packaging materials, electronic parts, containers, car parts, accessories, and much more.

One example of the production of plastic sheet products by vacuum forming is a corner shower cabin, shower tray.

Depending on the required characteristics, the material, sheet sizes, thickness and color are selected. We ship sheet plastic, from which the Customer uses his equipment to vacuum form the product of the desired shape in accordance with the design.

You can see the process in more detail on this video from youtube.

Marginality

The average markup on final products depends on many factors, such as the cost of materials, equipment, energy and labor costs. However, in general, the production of plastic products can be quite profitable.

One of the main advantages of using vacuum forming is the ability to quickly produce a large number of products with high precision and quality. This makes this technology particularly attractive for mass production.

For more accurate commercial figures, you can contact us and we will advise you in more detail.

Our contacts will be at the end of the article or in the profile.

Attachments

Firstly, you will need a room for production. We recommend a free 30-40 sq. m. for one medium molding table. And do not forget about the storage space for raw materials - sheet plastic and finished products.

Equipment for vacuum forming, which, by the way, we can also manufacture according to your tasks and ideas.

In most cases, only 1 person is required for one molding machine. And one person for further processing.

Demand

Consumer demand for vacuum-molded plastic products has grown significantly in recent times. Such products are inexpensive and durable, which makes them attractive to consumers. They are being introduced into all large areas, thanks to consumer qualities. To embody the ideas of designers, the plastic can have any color and texture.

As a confirmation, we can attach a graph of the total growth in the production of virgin plastic over the years from Plastics Europe (Association of European Plastics Manufacturers).

Summarizing all the above, we can say that the production of plastic products from sheet plastic using vacuum molding can become a profitable and promising business in Russia. It is important to consider the limitations of technology and analyze the demand for products in order to succeed in this industry.

You can contact us for a free consultation. We will tell you more and in more detail on your specific direction.

Our website: https://promplast-russia.com

Hot line: +7 800 700-99-43