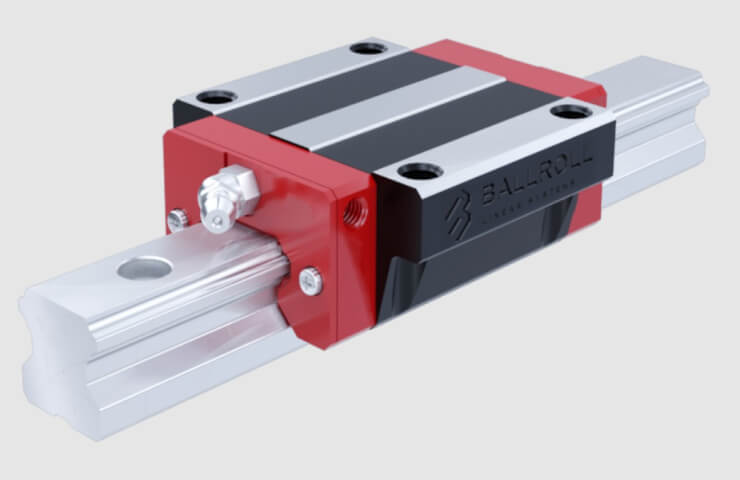

Modern CNC machines (CNC) require high stability, precision and reliability when performing operations. Linear motion carriages are one of the most important components providing these characteristics. They are responsible for smooth and precise movement along the axes and directly affect the quality of machining parts. You can find an example of such carriages here.

The role of the carriage in the machine design

A carriage is a movable assembly that moves along a linear guide, ensuring the movement of a tool or a worktable. Paired with ball or roller elements, the carriage guarantees stable sliding without backlash and with minimal resistance. The higher the accuracy of the carriage, the more stable the tool path, which means the higher the processing quality.

Carriage types and their features

The most common type in CNC machines is profile rail guides with ball carriages. They provide high rigidity, can handle heavy loads, and at the same time maintain accuracy throughout their entire service life.

Some machines use roller carriages, especially if increased load capacity and vibration resistance are required. They are more common in heavy processing centers and industrial equipment.

There are also miniature linear guides used in CNC engravers, laser and milling machines for the jewelry or electronics industry.

Precision and preload

The carriages are classified according to accuracy classes: standard, high and ultra-precise. Most household and mid-range machines use standard models, but when working with micro-machining or 3D metal milling, carriages with increased accuracy are chosen.

Carriage preload is another important parameter. It eliminates the gaps between the guide and the moving part, increasing the rigidity of the system. However, excessive preload increases friction and can accelerate wear if selected without taking into account the actual load.

Impact on machine operation

The carriage defines:

-

The geometry of the tool movement;

-

No backlash when changing direction;

-

The ability to withstand the weight of the gantry, spindle and other components;

-

Vibration level at high processing speed.

Even if the machine has a powerful spindle and a rigid frame, low-quality carriages can negate all accuracy, causing bumps, bumps and inaccuracies in parts.

Service and reliability

The carriages require regular maintenance. It is important to monitor: the condition of the lubricant; cleaning from dust and chips; absence of