Hydraulic equipment has a fairly wide range of applications. It is used to increase the force required to lift or move a load (for example, a tipper body, a multi-ton hammer of impact press equipment). The main structural element of hydraulic boosters, through which useful energy is transmitted, is the stem. According to the existing technical parameters, its inner surface should be mirror-like and even, but as a result:

- Long term and difficult operating conditions.

- Poor quality hydraulic fluid and temperature differences.

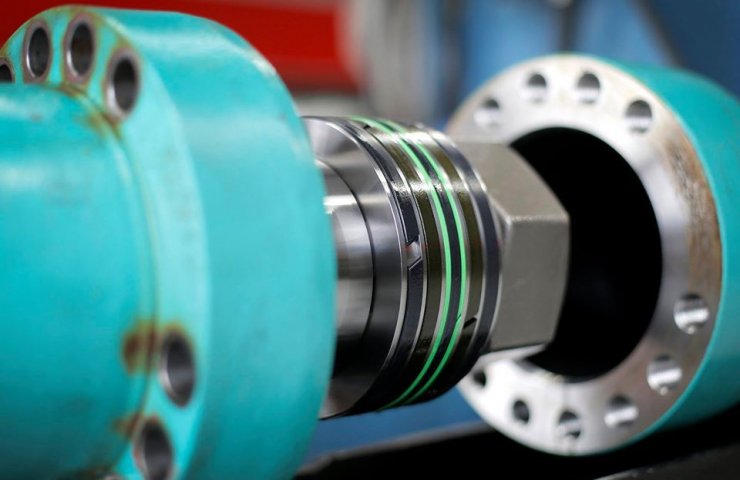

May be damaged in the form of scratches, chips, cracks and burrs. Cylinder rod repair if they occur, it is possible with special equipment and experience use in practice. This is how this technological procedure is carried out at HydroTechTrade.

Technology of restoration and repair of hydraulic cylinder rods

To restore the inner surface of the hydraulic cylinder rod at the own production base of the HydroTechTrade company, an advanced technology is used, consisting of 2 stages:

- Application of an iron-nickel alloy to the damaged surface.

- Grinding and polishing to original size along the entire length of the stem.

At the same time, the internal geometry does not receive any dimensional (spherical, diametrical) changes. The product after processing again meets the original factory parameters. This technique is used to repair and eliminate the following types of defects:

- Service wear, classified by professionals as "ellipse" or "barrel".

- Scratches and chips up to 7 mm deep.

- Traces of corrosion, often resulting from improper long-term storage.

This technology of restoration and repair of the inner surface of the rods refers to a rather complex, laborious (includes several operations), therefore, a costly category of work. But, its cost, even in the presence of the most complex defects, will be at least 2 times lower when compared with the purchase of a new part. You can get more detailed information on this issue using the website of the company "HydroTechTrade".