Manufacturing piece metal parts, or a small batch in a large factory, can cost a significant amount. Indeed, its cost will include not only the procurement and services of a turner, but also many related factors. Turning works to order https://fenixcnc.ru/uslugi/tokarnye-raboty.html , from a small company with a well-organized pricing policy is more profitable for the end consumer. All that is needed for this is to provide a drawing and terms of order execution.

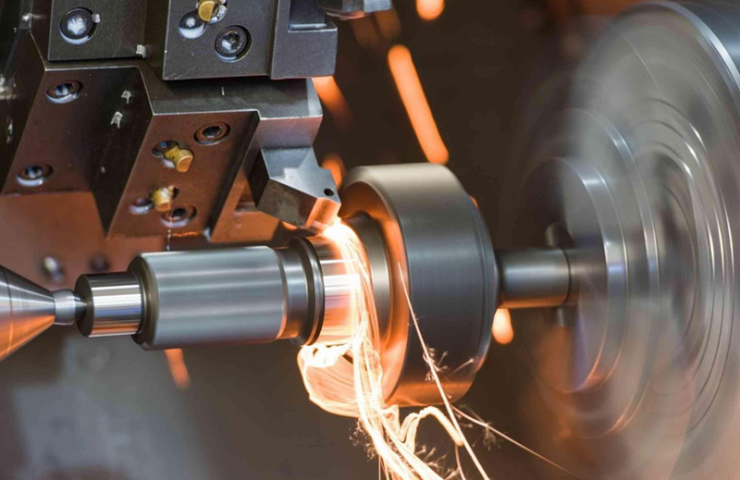

The importance of professional equipment

Precision machine tooling plays a key role in the manufacture of any part. Even the simplest machine, which has exhausted its resource, or not repaired in time, gives a significant error. This in turn affects the final product, which may not meet the customer's requirements. To other equally important indicators of the importance of equipment, you can add:

- order execution speed;

- Ability to process both soft metals and hard alloys;

- the scope of production of complex products is expanding;

- wide possibilities of physical dimensions of the workpiece;

- minimal amount of metal waste.

Professional equipment in the experienced hands of a turner is capable of producing any number of parts according to one template or drawing. In addition, the company has a wide variety of templates that allow the customer to avoid carrying out an independent search.

Reasons for good value

Preliminary and accurate calculation of the cost of work, a key point in the formation of a price that will not change in the future due to various circumstances. Professional metalworking on a machine involves a set of works to achieve the desired result. The main factors of affordable cost are:

- Use the most suitable size blank.

- No unnecessary actions on the part of the turner.

- Precision the first time.

- The economic approach of the enterprise itself.

An individual approach to each of the orders is very important. It is better to immediately stipulate all the important points before the execution of the order, than later to face its alteration. This not only increases the cost of the work, but also increases the waiting time for the required part. In many cases, the customer can count on the minimum waiting time, due to the competent loading of each individual turner and machine.