Choosing a manufacturer of metal structures is a strategic decision for any industrial enterprise. The safety of equipment, the durability of buildings, the efficiency of logistics and the absence of downtime depend on the quality of structures. Mistakes in choosing a contractor lead to budget overruns, delayed installation times, operational problems, and even accidents. Therefore, the company's task is to evaluate the manufacturer not only by price, but also by technological competence, certification, quality of materials and reputation.

Technological base and compliance with production standards

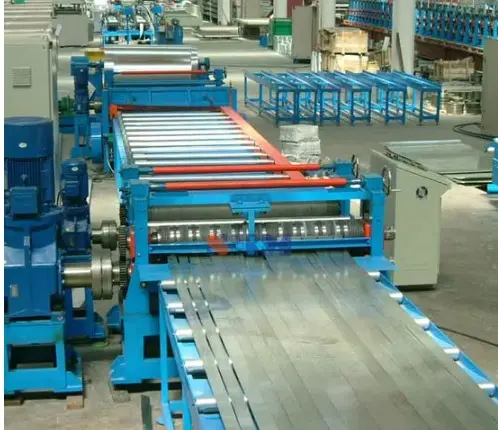

The first thing to check is the technical capabilities of the plant. A reliable manufacturer uses modern equipment: CNC machines, automatic cutting, bending, drilling lines, and robotic welding stations. This ensures the precision of the parts and stable quality.

The level of standardization is equally important. The manufacturer must work according to GOST, JV, have a regulated quality control system, and for complex facilities, ISO certificates and welding production certificates.

Special attention is paid to staff qualifications: engineers must work confidently with KM/KMD documentation and 3D modeling. The higher the technological maturity of the enterprise, the fewer the risks of obtaining a design that requires fitting during installation.

Real product quality: materials, control and traceability

The quality of the products is determined not only by the project, but also by how the plant adheres to the technology in the manufacture of metal structures. A reliable manufacturer works exclusively with certified steel and can provide documents for each delivery of rolled metal.

It is important to check how the control is carried out at the factory:

- steel entrance control;

- visual and measuring geometry control;

- ultrasonic and magnetic powder inspection of welds;

- control of the thickness and adhesion of the anti-corrosion coating;

- reconciliation of products with KMD drawings;

- marking of parts and maintenance of quality certificates.

The presence of control standards and documentation of all stages is a sign of a reliable manufacturer. The structures must be supplied fully equipped, with passports and specifications, and not "by eye".

Reputation, portfolio, and experience working with industrial facilities

Even high-quality equipment doesn't mean anything without experience. The manufacturer of metal structures must prove his competence in projects of a similar scale and complexity.

What you should pay attention to:

- portfolio of large industrial enterprises