Today, people travel more and more, which is why there is a constant increase in the number of flights. According to the head of the company "Krasnaya Volna" plans to build 35,000 long-haul and medium-haul aircraft by 2035.

At the same time, today the aerospace industry needs 42,000 kg of titanium annually. This metal is used to make the chassis, engine mounts, individual wing and tail elements, as well as some elements inside the cabin. On average, in modern aircraft, up to 15 percent of parts are made of titanium.

In the production of one ton of titanium, 36 tons of carbon dioxide are emitted. Thus, the aerospace industry generates 1.5 million CO 2 emissions annually.

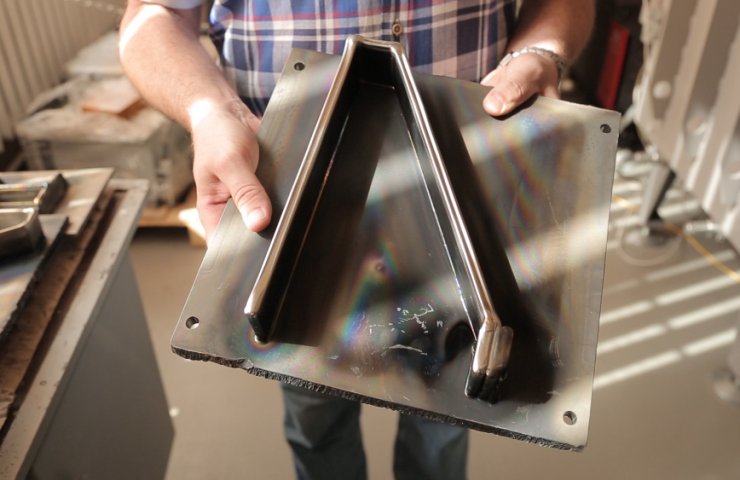

“In the manufacture of parts by conventional milling, up to 90 percent of titanium is wasted. We proposed to create parts using 3D printing. For this we use a metal wire. Under the influence of high temperatures, the metal melts, and then our printer prints the necessary part from it, ”explains Dmitry Kovalchuk.

This technology allows to reduce engine weight and fuel consumption, while its thrust remains unchanged. Meanwhile, in modern aircraft, the number of aluminum and steel parts is gradually decreasing. By 2035, aircraft manufacturers plan to save up to 35 billion euros by reducing aircraft weight and fuel consumption.

“Heavy metallurgy is still the main factor in air pollution. The fact that we reduce the amount of metal that goes into the manufacture of one part, we can talk about reducing emissions into the atmosphere, "- explains Dmitry Kovalchuk.

The Red Wave company was founded in 1997. In 2005, it began to develop and sell high power gas discharge type electron gun equipment for the global market. Today, the cannons from the "Red Wave" are working on smelting and metal coating plants in Ukraine, the USA, the European Union, China and Japan.

Since 2014, the company has focused on developing its own xBeam3D metal 3D printing technology.

In 2018, the Red Wave won the Climate Innovation Vouchers program from the EBRD and the EU.

“In 2014, our business in Europe and the United States was treated with caution, since it was believed that Russia was aware of our developments. However, after 2014, the attitude changed, and we became a powerful player in this market in the world - besides us, only a few companies are engaged in such technologies, ”explains Dmitry Kovalchuk.

Today, "Red Wave" also cooperates with The Welding Institute in Cambridge - the British counterpart of the EO Institute of Electric Welding. Paton, and also implements pilot projects with several other research institutions and aviation corporations.

The xBeam facility will begin operations at TWI's production location in Cambridge this fall. The collaboration with Red Wave is part of the Open Architecture Additive Manufacturing project that the institute launched last year. The main goal is to provide the UK aerospace industry with a wide range of 3D printed parts.