The EVOBLAST Group, a developer of innovative solutions for drilling and blasting operations (BVR), announced the completion of pilot tests of a new stationary control cabinet for mixing and charging machines (SPM) with a lifting capacity of 4 tons, operated during underground mining operations. The fully Russian development has become a significant step in the digitalization of underground mining operations to increase their safety and efficiency.

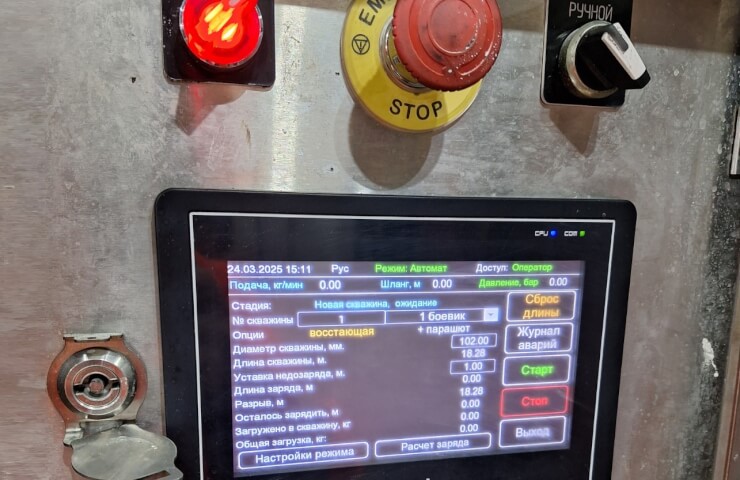

The software and hardware complex created by the specialists of the EVOBLAST Group optimizes the process of charging wells with an emulsion explosive (EVV). The system is based on modern Russian software version 5.XX with an intuitive interface that allows the operator to easily control the main stages of well charging operations. The multifunctional SPM controller ensures high accuracy of all operations, including automatic measurement of well depth, real-time correction of charging parameters, control of the charging sequence by unit and installation of intermediate detonators with precise positioning.

All functions are displayed on a single control panel in the car, and are also available for remote control via a tablet via Wi-Fi or 4G. This allows you to keep detailed records of the consumption of explosives, continuously monitor the quality of drilling and blasting operations and promptly make necessary adjustments to the work process. The all-welded stainless steel housing provides increased protection and resistance to extreme underground work conditions.

The idea of creating a new SPM control cabinet appeared in response to a request from a mining company. The specialists of the EVOBLAST Group selected the platform, developed a prototype and handed it over to the customer for testing. The solution was highly appreciated – immediately after passing the pilot tests, an order for several controllers was received. The company plans to adapt the development for machines with lifting capacities of 1.3 and 2.3 tons and expand the functionality of the system.