Quality industrial ball valves are produced by PERRIN GmbH. The German company develops and sells fittings of all types. Consumers describe PERRIN products as very reliable. PERRIN industrial ball valves have been successfully operating under high pressure, at extreme temperatures, in the most critical conditions.

What industrial ball valves can be bought

PERRIN industrial ball valves are repaired only after 30 years of successful operation. The fittings are maintenance-free. Industrial ball valves are produced:

- Two-way.

- Multi-pass of different designs.

- Accessories.

Two-way valves can have a two- or three-piece body. Spring loaded seats provide reliable sealing and eliminate leakage. The design of the crane is designed in such a way that the force is transmitted through the support trunnion and the drive shaft. Therefore, the ball valve with the ball in the bearings compared to the floating version has a lower torque. This means that it can be used with large nominal diameters and pressure stages.

Industrial multi-way ball valves with a ball in bearings are made with a two- or multicomponent body. The ball and the drive shaft are one piece. Thanks to such a well thought-out design, even at a high switching frequency, there is no backlash or wear at the interface of these parts.

Industrial ball valves are produced with different openings: L, T, X. Therefore, you can choose shut-off valves according to the individual requirements of the customer. The cranes distribute the working medium in different ways. Shut-off valves are widely used in various fields:

- industry;

- in the oil and gas industry;

- in shipbuilding.

At the request of the customer, PERRIN can use special materials in the production of ball valves, make special connections, flushing holes and heating or cooling jackets, low-temperature inserts.

Features of industrial ball valves

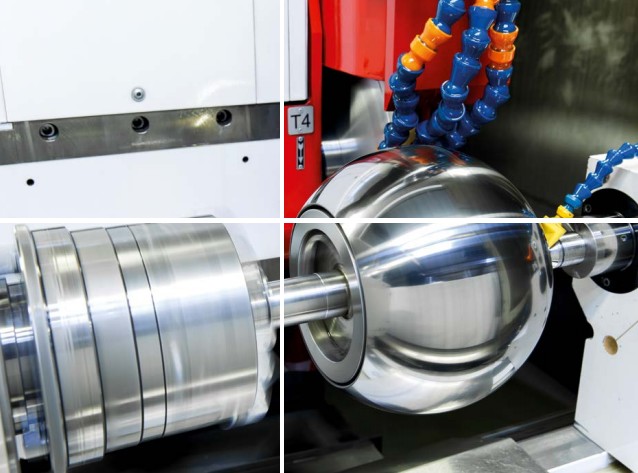

Metal sealed industrial ball valves are coated with various types of materials, depending on the needs of the customers. The valves are processed with innovative grinding and lapping technology. Therefore, a perfect 100% seal is achieved.

Industrial ball valves are equipped with an actuator:

- pneumatic;

- electric;

- hydraulic.

In the production of valves, carbon and stainless steel, titanium and various special materials are used. Therefore, it has been successfully operated for many years at extreme temperatures from -196 0 С to +800 0 С.

Due to the floating design of the ball of the two-way valve, a complete tightness is achieved at the outlet, increasing as the inlet pressure rises. Stop valves are sold from DN 15 to 600, and PN from 10 to 2500. Sealing can be carbon, soft, metal.

Some types of testing of manufactured products are performed with a coverage of 100%. Therefore, supplies of low-quality shut-off valves are excluded. A standard acceptance test for tightness and pressure resistance is carried out. Testing for cryogenicity, helium leaks is possible.

During the tests, an automatic test bench for nominal internal diameters is used, a three-dimensional measuring machine designed to measure the roundness of balls. Having installed PERRIN industrial ball valves, you don't have to worry about their performance and leaks. The shut-off valves of the German company have proven the best quality in practice.