Modern technology operates in harsh environments, facing many negative factors: high temperatures, dust, water, shock and vibration. All this leads to the gradual destruction of components, reducing the service life and increasing the frequency of repairs. Fortunately, modern electrical insulating filler compounds that can significantly prolong the life of devices help to solve the problem.

Why do we need electrical insulating filler compounds?

Before we talk about the service life, let's define the role of filling compounds in the device technology.

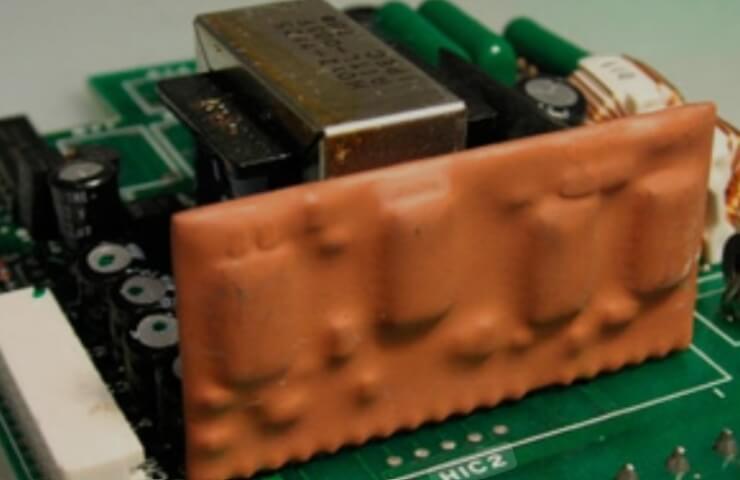

The purpose of the compound is to create an airtight layer around the components, preventing the ingress of moisture, dirt and oxygen. In addition, the compound stabilizes the internal parts of the device, keeping them stationary relative to each other, which reduces the impact of vibrations and shocks. Thus, the part receives additional protection from physical wear and electrical overload.

Filler compounds are especially important for protecting micro-components, such as integrated circuits, capacitors, and transistors, as they reduce the likelihood of accidental short circuits and maintain a low degree of contact oxidation.

How do electrical insulating filler compounds improve the reliability of machinery?

Modern electrical insulation compounds have several useful properties that improve the performance of equipment.:

- Waterproofing ability: The compound creates a waterproof barrier that protects the device from moisture and condensation.

- Thermal conductivity: Some grades of compounds have improved thermal conductivity, helping to remove heat from critically stressed areas, thus reducing overheating.

- Chemical neutrality: modern compounds are chemically inert and do not react with circuit components, do not cause corrosion of metal and plastic.

- Noise reduction: Sealing the components eliminates extraneous noise and vibration, making the device quieter and more comfortable to use.

- Anti-vibration properties: the components fixed inside the compound become more resistant to shocks and impacts, which is useful for mobile devices, transport and industrial equipment.

The principle of operation of electrical insulating filler compounds

The principle of operation of filling compounds is quite simple: the liquid compound is poured into a pre-prepared container or cavity of the device body, filling the space between the circuit elements. Then the compound freezes, turning into a solid mass that fixes the components and prevents their displacement. The finished compound layer turns out to be hard, flexible and impervious to water, oils and many chemicals.

Exactly