Metal cutting involves the use of various types of machine equipment. The technology is selected taking into account the assigned tasks and the specifics of the production processes. Band sawing machines are used quite widely and allow you to automate the processes of cutting elongated workpieces (rods, pipes, profiles). metal band saws used as a cutting element must meet the following requirements:

- Standard dimensions for a certain type of serial equipment.

- Resistance to high temperatures encountered during cutting.

The technology for using this type of equipment involves supplying coolant to the cutter. The product should not enter into chemical reactions and maintain its geometry during temperature changes.

Classification by type

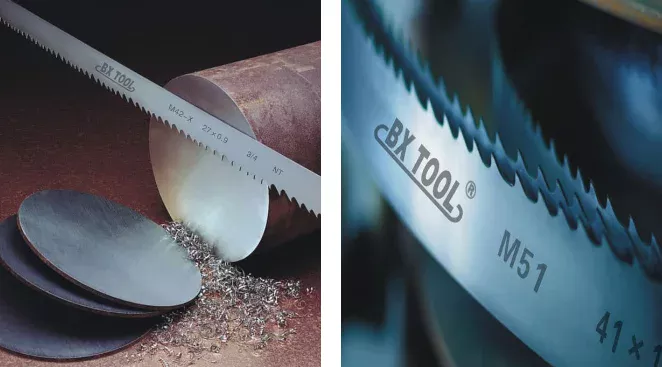

Branded carbide saws are classified taking into account the shape, angle of rotation and pitch of teeth located in one row. The following types are distinguished:

- Standard with a triple pattern - left inclined, right and straight teeth. Suitable for processing all grades of steel.

- Variable position - right, left and stripper. Used for soft and brittle alloys.

- Wave setting - allows you to cut thin-walled profiles or rolled pipes.

Modern technologies for hardening, setting and sharpening of tooth edges allow the use of band saw machines with high accuracy of the dimensional parameters of the cut products . Branded saws have a long service life and a long time for performing non-stop operations.

Wide selection and assistance in selection

Familiarize yourself with the types and technical capabilities of carbide band saws, as well as metal laser machines , guillotine shears, press brakes, you can use the official website of the NPP FOST company. The items presented in the catalog are branded products from well-known manufacturers. Free consultation on the selection of the right product is carried out by a full-time specialist of the company. The purchase process is carried out online with the possibility of ordering delivery to any region of the country.