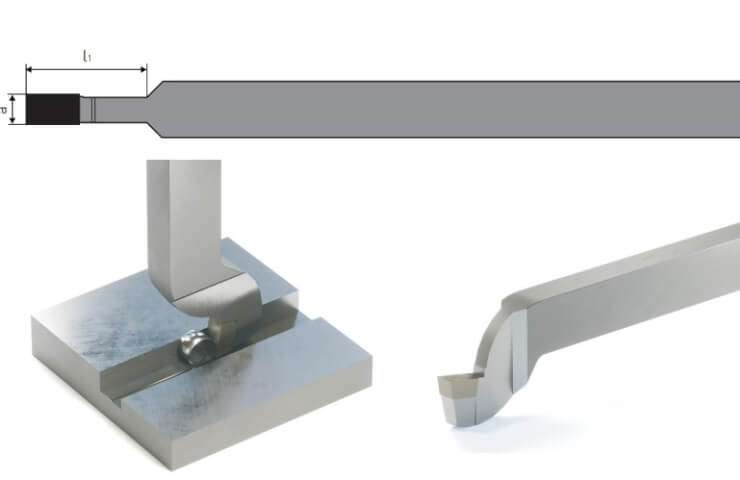

Metal surface treatment is a laborious and demanding process that requires attention to many details. Many craftsmen face a number of difficulties that can lead to marriage, unnecessary time and material costs. Often the problem lies in the wrong choice of tool, non-compliance with technological standards or lack of sufficient experience. In this article, we will look at the main difficulties encountered in planing metal, and propose effective ways to solve them using the example of a planing cutting tool.

Problem No. 1: Surface deformations

Very often there is a situation when, after planing, the surface turns out to be wavy or bumpy. The main reasons for this are:

- Insufficient clamping force of the workpiece to the machine table.

- Damage or deformation of the base plates and rollers of the machine.

- Poor-quality sharpening of the planing cutting tool.

Decision:

- Make sure that the workpiece is firmly fixed on the machine table.

- Check the condition of the machine's support elements and replace them if necessary.

- Check the condition of the cutter regularly and, if necessary, sharpen or replace it.

Problem #2: Surface roughness

The metal surface may have a grainy or pock-marked texture after planing. The main causes of roughness:

- Incorrectly selected cutting angle.

- Low feed rate or too deep removal of the material.

- Heating of the surface during planing.

Decision:

- Use the correct cutting angle specified in the machine's data sheet or manufacturer's documentation.

- Adjust the feed rate and removal depth of the material.

- Use a special coolant or oil lubricant to prevent overheating.

Problem #3: The formation of nicks and cracking of the surface

The surface may be covered with small cracks or notches, which spoils the appearance and violates the technical characteristics of the part. The main causes of defects:

- The sharpening angles of the cutter are too sharp.

- Great effort when feeding the workpiece.

- The presence of debris or impurities on the working table of the machine.

Decision:

- Replace or re-sharpen the planing cutting tool in compliance with the recommendations on the sharpening angle.

- Control the feed force, reducing the load on the workpiece.

- Clean the machine table and the surface of the workpiece regularly before starting work.

Problem number 4: The appearance of comb marks

Characteristic stripes remain on the treated surface, similar to the teeth of a comb. This is caused by:

- By tilting the cutter or shifting the machine table.

- Exhaustion