Designing plastic injection molds is a complex process that includes several important steps. The correct implementation of each of them guarantees the successful creation of functional and efficient tooling. In this article, we will look at the main stages of mold design, as well as offer practical recommendations for achieving the best results.

Mold design Stages

- Technical task analysis The first step is a detailed study of the customer's requirements. It is necessary to determine the parameters of the future product: shape, dimensions, tolerances, operating conditions and the desired material. These data help designers choose the most appropriate casting method and type of mold.

- Concept development Based on the analysis of the terms of reference, the concept of the future mold is being created. Important elements such as the number of sockets, the location of the gate channels, the cooling system, and the mechanisms for removing finished products are determined. It is important to take into account the manufacturability of the design in order to minimize the risk of failure and simplify further operations.

- Modeling and simulation Modern computer modeling methods allow you to evaluate in advance the behavior of plastic inside the mold. With the help of special programs, you can simulate the process of filling the mold cavity with melt, identify possible problems with filling or cooling, and make adjustments before production begins.

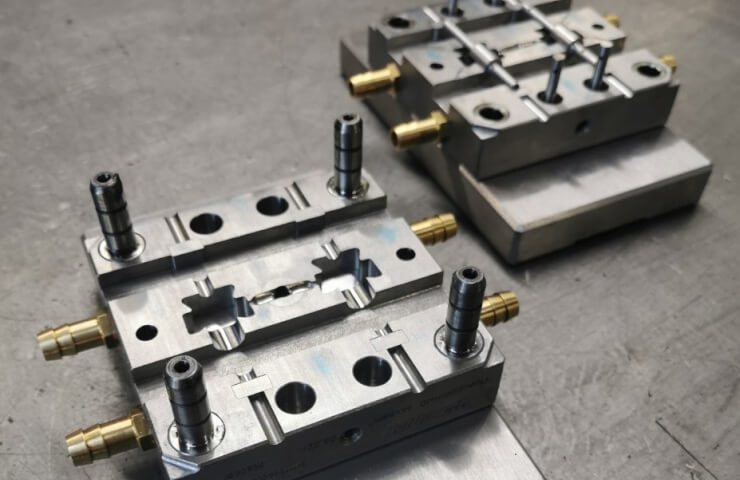

- Constructive development After the approval of the conceptual solution, the detailed design of individual mold components begins. Special attention is paid to nodes subject to high loads, such as guide columns, pushrods and locking joints. The use of high-quality materials, such as hardened steel, helps to increase the life of the tooling.

- Preparation of documentation The final stage of the design part is the preparation of a set of drawings and specifications. The documentation should contain all the necessary information for the manufacture of the mold, including dimensions, tolerances, materials and surface finishing requirements.

Key decisions in mold design

- Optimization of the cooling system: the correct placement of the cooling channels ensures an even temperature distribution inside the mold, which prevents deformation of the products and improves their mechanical properties.

- Minimization of shrinkage: taking into account the shrinkage coefficient of the material during the development of the mold allows you to obtain a product with a given size and shape.

- Efficient injection system: well-positioned

Сomments

Сomments (0)

On this topic