September 3, 2020

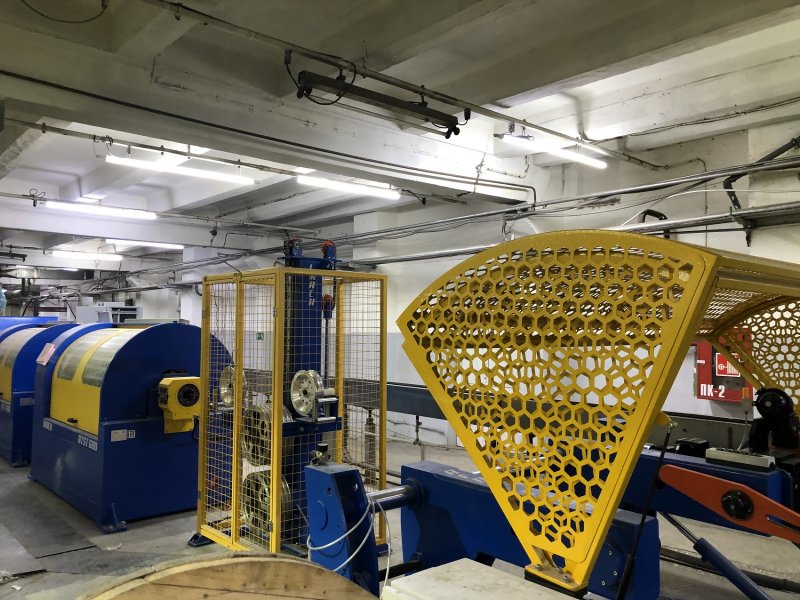

Tomsk plant "Sibkabel" (part of the "Cable Alliance Holding", which unites the cable assets of UMMC) has modernized the equipment used in the production of products for rolling stock. Shop No. 40 has a high-tech double winding line, the productivity of which is 3 times higher than that of the previous analogue.

The cost of the equipment is about 17 million rubles. It is intended for wrapping bare and insulated conductive conductors (TPG) with a cross-section from 10 mm² to 300 mm² PET-E film and other tapes.

“Electrical insulating film (PET-E) has improved dielectric characteristics, resistance to impact corrosive chemical environments, increased mechanical strength ", - explained the head of shop No. 40 Sergei Osokin.

In the process of cable production, tape winding is carried out in two stages. The first layer is a separating layer between TPG and insulation. It excludes the ingress of polymeric insulating materials into the interwire space and makes it easy to remove the insulation from the core, which, in particular, facilitates cable installation.

The second layer of tape is applied to the insulated core and serves as additional insulation, providing the necessary electrical resistance and strength. The number of applied tapes depends on the operating voltage: at 1000 V, one tape is required, at 2000 V - two and then on an increasing basis.

“The plant is constantly improving technological processes. This allows you to optimize the use of resources, increase productivity and work efficiency. We promptly respond to new market requirements, and sometimes even anticipate them, which allows us to expand cooperation with existing customers and attract new ones, ”said Alexey Zhuzhin, director of Sibkabel JSC.