The need to search for foreign metal particles is necessary not only in the food industry. Even a small piece of metal in the building mixture can negatively affect the quality of the product and the reputation of the manufacturer. High-quality and reliable metal detectors at enterprises allow you to catch foreign particles in a timely manner. Do not allow them to end up in the packaging with the main product.

Technical features of industrial designs

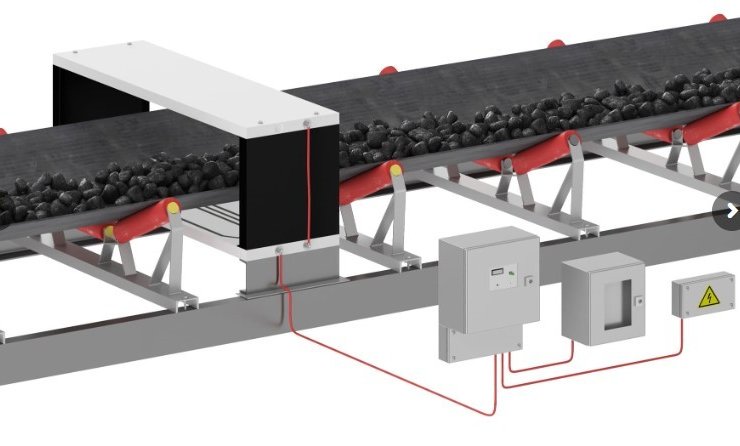

The choice of a model can be complicated by various technical requirements for the scanned product or bulk material. In order for the selected model to show maximum efficiency in practice, the metal detector must be selected according to the following parameters:

- The speed of the conveyor belt with the scanned product.

- The size of the opening through which the raw material will move.

- Sensitivity to different types of metals and alloys.

- The size of the metal particles to which the equipment responds.

- Hypersensitivity to ferrous metals and their alloys.

It is important that the equipment remains operational, despite the increased moisture content of the raw materials, the heterogeneity of particles and the possible impregnation of other impurities. Timely metal capture not only improves the quality of the product, but also sort the waste if metal detectors are used in the waste sorting industry.

Important Factors of Choice

Since the equipment will face a wide variety of negative operating factors, it is worth taking care of some additional important characteristics. Some can be neglected, but together they will make the metal detector as reliable as possible for a long time in everyday use:

- automatic rejection or extraction of metal particles;

- belt width and adjustable feed rate;

- dimensions to fit in an industrial building;

- protection from sparks and other factors of explosion and ignition;

- protection against moisture and dust, which are unavoidable in an industrial environment.

Important: the help of narrow specialists in this matter will not be superfluous. But, even with this information, you can confidently bring production to a new level. The absence of metal objects in bulk building, combustible materials helps to achieve consistent quality. Conversely, inclusions can cause losses and well-founded claims from the consumer.