Engraving is the process of applying inscriptions and images to the surface of a material. It is obtained either manually or mechanically. The first one is too laborious, it requires not only time, but also increased efforts on the part of the master, high professionalism, especially if the drawing is applied to metal. In practice, it is rarely used. The most widespread is laser engraving on metal. It allows you to apply lettering, logos and other drawings with high fidelity of the original image and impressive speed.

Features of the technological process

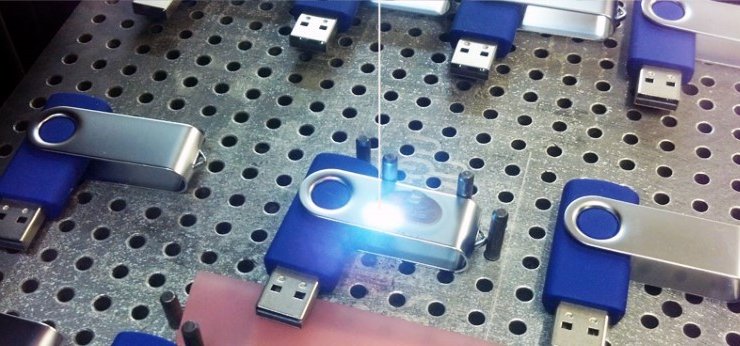

Laser engraving technology involves the use of a special machine, as a working body of which a powerful flow of energy is used, focused into a thin beam - a beam. Such equipment can also be used for cutting metal, but it can also act on the surface layer of the workpiece, thereby providing the possibility of engraving.

Laser engraving on metal can be done in two ways:

- The surface layer is pointwise heated to the melting point. During the transition between phase states, physicochemical changes occur in the material, correcting the structure. In this way, you can get both regular and color engraving.

- The laser heats the surface of the product to the vaporization temperature of the material. By changing the radiation power, you can adjust the depth of the removed layer, up to hundredths of a millimeter, thereby changing the relief of the pattern or the relief structure of the pattern.

Benefits of laser engraving

Compared to other engraving technologies, laser engraving has a number of significant advantages:

- the ability to receive pictures and inscriptions on any metals: steel, aluminum, cast iron, titanium, brass, silver, gold, platinum, etc.;

- high precision of detail, regardless of the size of the picture;

- absence of mechanical contact of the working tool with the surface excludes its contamination, deformation;

- the image is resistant to abrasion, fading;

- no finishing required: the final image is obtained immediately;

- no subjective errors: the process is fully automated.

The metal laser engraver is highly efficient. You can familiarize yourself with the equipment on the website LLS Mark ... The products obtained on it surpass the results of manual, mechanical, sandblasting, electrochemical engraving in many respects, and have no analogues.