Metalworking plays a key role in the life of modern society. Without it we wouldn't have in other industries, such as manufacturing, automotive, aerospace, information technology, and many others. The metal can be used for further purpose, it is necessary to prepare, that is, to give it the desired shape, dimensions, etc. this helps the treatment process.

the following are the common types of metals used in various sectors and industries.

machining

these types of training and the formation of metal structures are manufactured using different tools:

-

the

- with a predefined geometry of the blades (turning, milling, sawing); the

- without a specific cutting tool (grinding); the

- with a free sharp edge (lapping, polishing, honing); the

- without the use of blades (ultrasonic, water jet, plasma and laser process).

Each of these methods has its advantages and disadvantages. The choice of method of metal depends on the future use of metal products, that is, from the necessary accuracy and quality of the obtained sheet.

Manual handling

Shaping metal by using hand tools such as blades, sand paper etc. Requires physical effort.

Manual Metalworking can be divided into:

-

the

- wood; the

- drilling; the

- grind; the

- cleanup; the

- protection (e.g., paint).

Processing sheet can be carried out by both machine and by these methods. Often manual format is used for small sheets or the final work with metal.

Heat treatment

This impact implies the effect of heat on metal structure on the microstructural level to change its properties. The most common type of material that is subjected to heat treatment, is steel. The main reasons for the use of thermal method on the enterprise OOO NPP "rich" ltd-rich.com — increase strength, increase toughness and/or shape change of the structure.

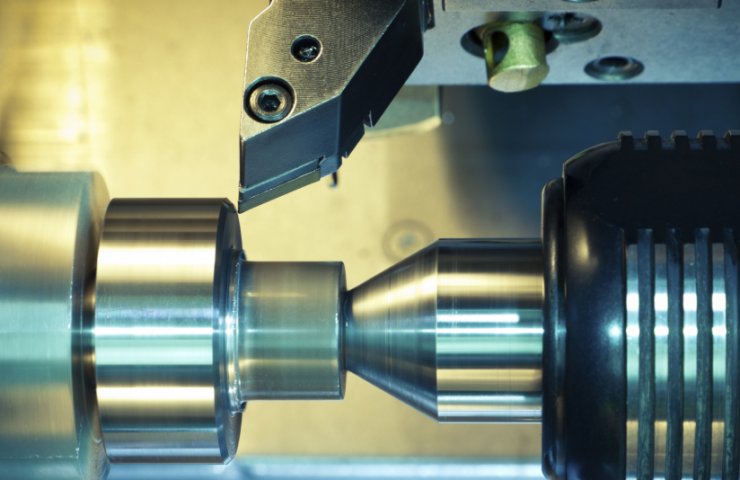

metal Processing using CNC machine

metal Cutting machine with computer numerical control (CNC) is a tool which is used for processing metal parts by separating the particles. The technology offers many benefits, primarily related to speed and accuracy. The process occurs on a machine with pre-defined tools.

One of the main advantages of using CNC in metal processing is the ability to execute complex projects with digital process automation system CAD-CAM. It uses the commands for three-dimensional drawing. The main drawback is the large quantity of generated scrap. However, he kompensiruet high quality, accuracy and speed. Because the machines replace human processing error is minimized.