Machining deep grooves on lathes is a difficult task, fraught with many difficulties. One of the main problems with deep cutting is the vibration of the tool. The causes of vibration may be incorrectly selected cutting modes, incorrect attachment of the tool, or defects in the workpiece itself. As a result, there is a deterioration in the quality of processing, a decrease in tool life and a potential danger to the operator.

In order to prevent the occurrence of undesirable fluctuations and maintain high-quality processing, several basic recommendations should be followed. One of them concerns the tool itself — the turning tool for grooves.

Causes of vibration when processing deep grooves

The main causes of vibration when processing deep grooves are:

- Insufficient rigidity of the tool attachment.

- Incorrect cutting modes (too large feed, high rotation speed).

- Defects in the workpiece (loose fixation, curvature, internal stresses).

- Poor tool sharpening or damage to the cutting edge.

Each of these reasons can cause severe tool fluctuations, impair the quality of processing, and accelerate the wear of expensive equipment.

Ways to eliminate vibration when processing deep grooves

Vibration elimination is a set of measures aimed at ensuring the stability of the cutting process. Some of the ways to reduce vibration include:

- Increasing the rigidity of the cutter attachment. A properly installed and well-fixed device can significantly reduce the amplitude of vibrations.

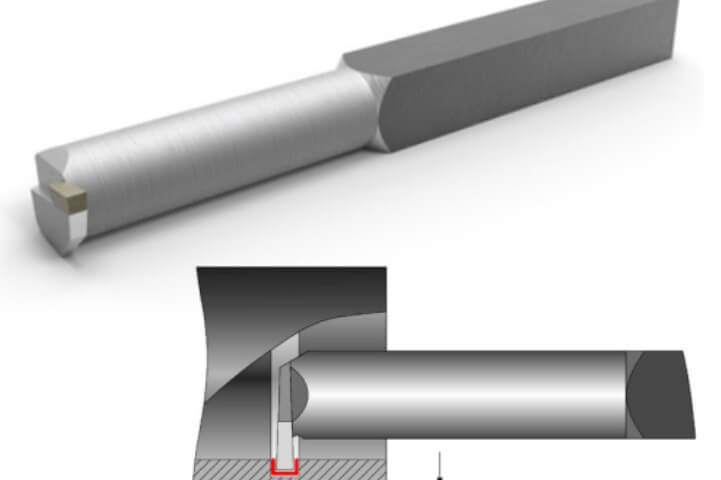

- The use of special tools. There are specialized turning groove cutters designed specifically for deep cutting. They have increased rigidity and reinforced construction, which helps to keep vibrations to a minimum.

- Adjusting the cutting mode. Extreme speeds and feeds should be avoided by regularly measuring the temperature of the cutting area and the force on the cutting tool.

- Checking the condition of the equipment. Even a minor malfunction or wear of the mechanism can cause severe vibration.

Features of choosing a tool for processing deep grooves

One of the key factors in preventing vibration is choosing the right tool. Standard cutters are often not effective enough when processing deep grooves, as they experience significant loads and are prone to destruction of the cutting edge. In this regard, it is worth paying attention to specialized