In the modern industrial world, mold manufacturing plays a key role in ensuring high-quality products and optimizing production processes. Thanks to new technologies and materials, the mold manufacturing process is becoming more efficient and faster. In this article, we will look at modern methods used to increase productivity and reduce the cost of manufacturing products by injection molding.

What are molds?

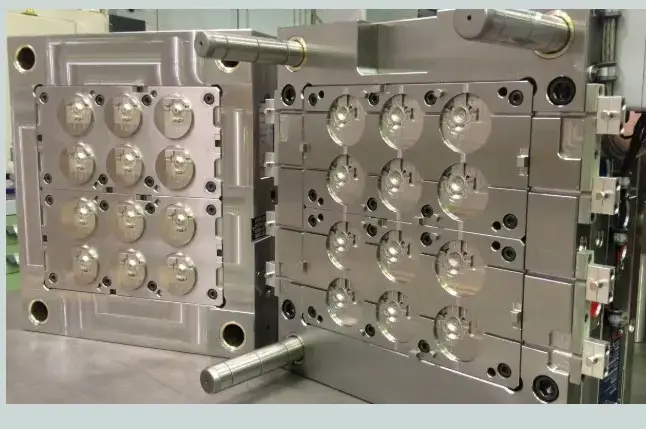

A mold is a tool used to mold parts by filling a cavity with molten material (most commonly plastic). It consists of two parts: a die and a punch, which are joined together to form the desired shape of the product. The quality of the mold directly affects the quality of the final product, so it is important to choose the right manufacturing method.

The main stages of mold manufacturing

The mold manufacturing process includes several key steps:

- Design and modeling.

- Selection of materials.

- Processing of workpieces.

- Assembly and testing.

Each stage requires special attention and professionalism of the performers, since even minor deviations can lead to defective products.

Modern technologies for the manufacture of molds

Today, there are several modern methods that can significantly improve the efficiency of the mold manufacturing process.:

1. CNC machining

The use of numerical control machines (CNC) allows you to create precise and high-quality molds. These machines are capable of processing the most complex surfaces with minimal deviations from the specified dimensions. This is especially important in the production of large batches of complex parts.

Advantages of CNC machining:

- High precision processing.

- The possibility of automating the process.

- Reducing the time required to prepare the instrument.

- Minimizing the human factor.

2. Laser cutting and welding

Laser technologies make it possible to produce mold elements quickly and accurately. For example, laser cutting is used to cut contours and holes, and laser welding is used to connect individual structural elements. This method ensures high speed and accuracy of work, reducing the likelihood of defects.

Features of laser cutting and welding:

- High-speed processing.

- No mechanical effects on the material.

- The possibilities of fine-tuning the laser power.

3. Additive technologies (3D printing)

Additive technologies, also known as 3D printing, are becoming increasingly popular in the manufacture of molds.