Impact strength shows how much energy a material is able to absorb upon a sharp impact without collapsing. This is the main strength indicator for metals, plastics, and composites, especially if they operate under dynamic loads. For such tests, pendulum copres are used — devices that measure the energy required to destroy a sample. The price of pendulum copra depends on the range of impact energy, configuration, availability of a thermal camera, and automatic data processing functions. The higher the accuracy and automation level, the wider the device's capabilities.

The two most common test methods are Izod and Charpy. Both were developed at the beginning of the 20th century and are still considered the standard in mechanical engineering, construction, and materials science.

The Izoda method

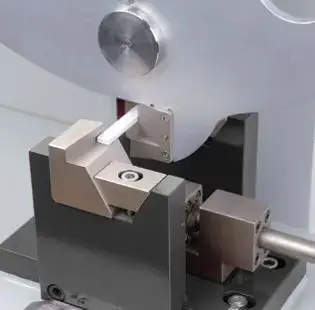

The method was developed by engineer Edwin Izod. In it, the sample is fixed vertically, and a blow is applied to the upper end from the side where the V-shaped incision is made. The pendulum falls on the sample, and the impact strength is calculated based on the amount of the fracture energy.

Used for:

-

Metal, plastic samples;

-

Comparative strength tests;

-

Control of stability of alloy properties.

Standards: ASTM E23, BS 131 for metals; ASTM D256 and ISO 180 for plastics.

The Sharpie method

French engineer Georges Charpy proposed a different scheme: the sample is positioned horizontally, and the pendulum strikes the center of the opposite side of the incision. This approach makes it possible to more accurately assess the behavior of the material under real loads.

The incision can be U- or V-shaped, depending on the fragility of the material.

The method is particularly in demand in the following industries:

-

Shipbuilding;

-

Energy industry;

-

Construction of bridges and pressure tanks.

Standards: ASTM E23, ISO 148, ASTM A370 for metals; ASTM D6110 and ISO 179 for plastics.

Let's look at the main differences between impact tests.

Why impact tests are important

Such tests show how the material will behave under severe mechanical stress, such as falling, impact, or vibration. This is critically important for machine parts, bridge elements, and equipment housings.

Besides, tests help:

-

Compare batches of materials by quality;

-

To control the stability after heat treatment;

-

To investigate the effects of aging and corrosion.

The choice of method depends on the tasks.:

-

If you need to evaluate the impact strength of plastic or small samples, an Isod is suitable.;

-

If you want to study the fracture toughness of metals, especially structural ones, it is better to use Sharpie.

In both cases, it is important to observe standards and accuracy.