In the world of industrial heating and cooling systems, everything is arranged almost like a human's: there is a "heart" — a pump, "arteries" — pipes, and "blood" — a coolant. But if water is the basis in the body, then it often becomes a problem in production. It freezes in winter, boils in summer, and the equipment is rusting… In general, no company can do without a reliable coolant.

Why is water as a heat carrier not always a friend?

Plain water is cheap and affordable, but its use on an industrial scale is fraught with trouble. At sub—zero temperatures, it turns into ice, bursting pipes, and at high temperatures, it causes corrosion and scale formation. That is why modern enterprises are increasingly choosing specialized heat carriers capable of withstanding extreme conditions.

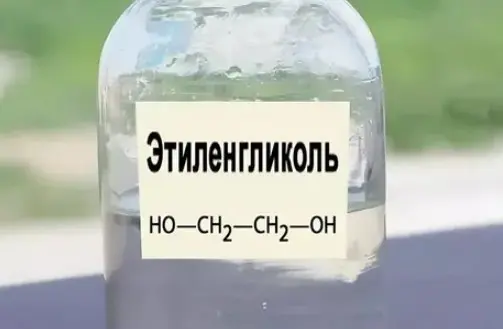

Ethylene Glycol: not just chemistry, but salvation for systems

Among all the options, ethylene glycol occupies a special place — an organic compound that reduces the freezing point of a liquid and increases its stability when heated. It not only prevents freezing, but also protects the equipment from corrosion due to inhibitory additives.

It is important to understand that not every ethylene glycol is suitable for industrial applications. The quality directly depends on who produced it. A reliable manufacturer guarantees the purity of the composition, accurate concentration and compliance with technical standards.

Bulk heat carriers: savings without compromise

For large enterprises, the purchase of heat carriers in bulk is not just a convenience, but a necessity. This allows you to:

- reduce unit cost;

- ensure uninterrupted operation for months ahead;

- avoid the risks associated with fakes or low-quality analogues.

In addition, when you buy ethylene glycol in bulk from a trusted supplier, you receive not only the product, but also technical support, recommendations for use and assistance in selecting the composition for specific tasks.

How to choose the "right" coolant?

Not all heat carriers are equally useful. When choosing, you should pay attention to:

- Operating temperature range;

- compatibility with system materials (aluminum, copper, steel);

- availability of certificates and technical documentation.

And remember: cheap doesn't mean profitable. Sometimes saving on quality results in expensive repairs or even a production shutdown.

Instead of a conclusion: the coolant is an investment

By choosing high—quality heat transfer media, you are not just buying liquid - you are investing in the stability, safety and durability of the entire system. And when