Many manufacturers of modern airborne equipment establish impressive warranties on their products. If you correctly select and buy a screw compressor , timely service, it can work up to 70,000 hours without major repairs. But, it should be understood that such impressive figures can be realized only under favorable conditions in production.

What affects the long life

Competent operation will avoid the most unpleasant state of any equipment, sudden breakdowns and stoppages of the production process. Compressed air is essential for many applications. And its absence in the piping system actually paralyzes the production process. To prevent this from happening, experts recommend listening to the following tips:

- Use only lubricating oil recommended by the compressor manufacturer.

- Disable equipment so that it does not run idle.

- Timely carry out technical inspection and replacement of consumables.

- Additional filtering equipment at the air mass inlet.

- Even minor damage should be fixed as soon as possible.

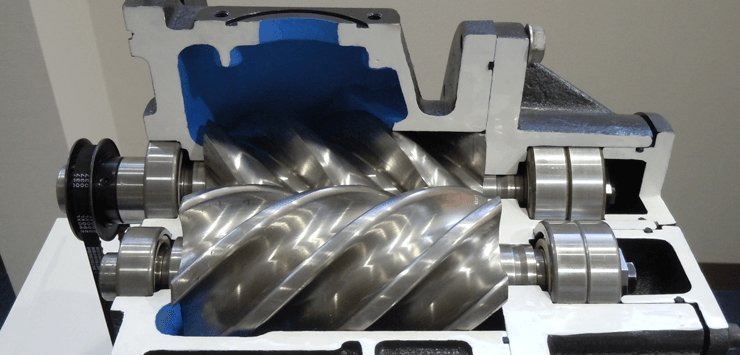

Important: the screw pair is the most important detail in the entire mechanism. It is she who is faced with the greatest loads in the process of pumping air. Lack of lubrication leads to almost instantaneous overheating and premature wear of the equipment. Compressor oil, a key consumable in everyday reliability.

Maintenance Highlights

Replacing lubricants and filter elements is only part of the operations that must be performed during periodic maintenance. If you do another, recommended list of works, the screw compressor will serve especially for a long time in any enterprise:

- replacing bearings as they wear out;

- checking that all wires are secure;

- preventive tightening of fasteners;

- valve train lubrication;

- mandatory cleaning of the cooling radiator.

Many manufacturers recommend doing basic maintenance every 2500-3000 hours. Professional Ingersoll Rand equipment can resist negative factors of operation for a long time. But, timely service will give him a particularly long life without any emergency breakdowns.