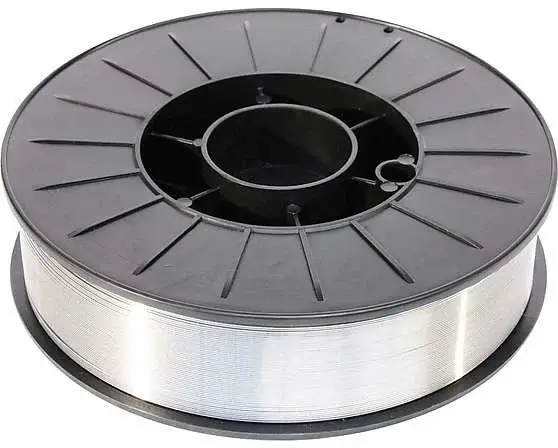

Welding machines are used not only in industry, but also in the domestic sphere. The right choice of consumables will allow you to get a high-quality, strong and durable welding seam. Demanded aluminum wire for semi-automatic machine presented in a wide range. But, even in this case, the choice must be made based on your own needs and the technical characteristics of the welding machine.

Complexities of the welding process

Aluminum and its numerous alloys, upon contact with atmospheric oxygen, almost instantly form oxide film. It is she who is the main obstacle to welding. Technologically, the welding process looks like this:

- immediately before the start of welding, the surfaces are protected;

- the use of inert gas to protect the weld;

- high-quality consumables in in the form of a special wire;

- observance of the welding process.

Recently, the industry has learned how to make special consumables. The composition of the wire includes a component that, at the time of formation of the weld, creates a local gas shield from atmospheric oxygen. Thanks to these chemical processes, the welding process is greatly facilitated and the result of joining two parts is increased.

Features of the choice of wire

Among a fairly wide selection of consumables, most welders prefer universal wire, with average technical characteristics. But, professionals always keep several options on hand in order to match the consumables as accurately as possible to the unique characteristics of the aluminum alloy. The following options are available for selection:

- Magnesium and silicon, as the main components of a universal wire.

- Different composition of the wire itself, more precisely aluminum alloy.

- Thickness consumables according to the capabilities of the welding machine.

- The melting point of the wire can also be important.

- The uniformity of the consumables is guaranteed by the manufacturer.

Don't focus on only on one or two characteristics. Each indicator is important in itself, but only all of them guarantee a high-quality seam when working with thin-walled metal and thicker workpieces. Welding aluminum becomes less of a challenge with the right choice of specialized semi-automatic wires.