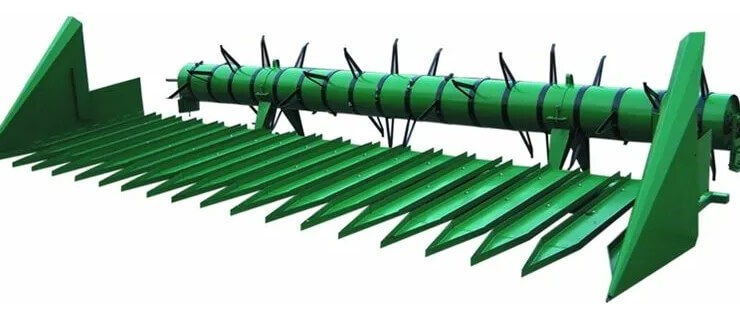

Sunflower harvesting requires the use of specialized machinery to minimize seed loss, speed up the process and maintain crop quality. One of the key elements of the harvesting campaign is the sunflower harvesting device, which directly affects the efficiency and cost-effectiveness of the combine.

If you plan to upgrade your fleet of equipment, pay attention to the sunflower harvesting device lifter, suitable for different models of combine harvesters and the working conditions of the farm.

Why do you need a specialized device for sunflowers?

Sunflower is highly sensitive to mechanical damage during harvesting, as well as to seed loss due to incorrect equipment settings. Universal harvesters do not always cope with high-quality harvesting of this crop, leading to high losses and increased costs for the harvesting campaign.

The use of specialized devices for harvesting sunflowers allows:

– minimize seed losses;

– reduce cleaning time;

– reduce fuel consumption;

– reduce the wear of machinery;

– increase the profitability of production.

Elevator-type devices carefully lift baskets of plants, carefully separate the seeds and send them to the hopper, reducing mechanical damage to the seeds and the number of losses.

The main criteria for choosing a device for harvesting sunflowers

1. Compatible with the combine.

Before buying, it is important to clarify whether the selected model is suitable for your equipment, taking into account the width of the grip, the type of drive and fasteners. Some models of lifters can be installed on combines from different manufacturers without modifications.

2. The width of the grip.

For large farms with large sunflower areas, it is advisable to choose models with a working width of 6 to 9 meters to speed up harvesting. Models with a smaller grip width are suitable for small fields and narrow driveways.

3. The design of the lifters.

High-quality models have lifters with the ability to adjust the height and angle of inclination, which allows you to adjust to the height of the stem and the density of crops. The adjustment helps to reduce the clogging of the harvester and increase the harvesting speed.

4. The presence of a shredder.

Some models are equipped with stem shredders that allow for immediate mulching of leftovers, which reduces the number of passes through the field and saves farm resources.

5. Materials and wear resistance.

The harvesting device must be made of high-quality wear-resistant materials that are resistant to aggressive operating conditions.