Heat exchangers transfer heat from a heated medium to a cold one. The devices are widespread in various fields - it is used everywhere (in cooling and ventilation systems, at heating points, in the chemical and food industries, metallurgy and the energy sector).

Main views

Heat exchange equipment is classified according to different criteria. By heat transfer, it happens:

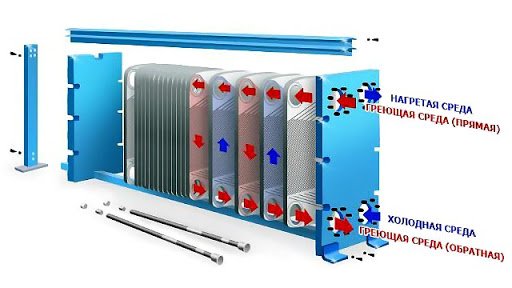

- Surface - carriers are cut by a plate through which heat is transferred through the thermal conductivity of the material. The amount of energy transferred between the heat carriers depends on the size of the wall.

- Mixing units are designed for mass and heat exchange processes through direct mixing of working media.

By application, heat exchange equipment is classified:

- shell-and-tube - pipes are fastened into a lattice by welding or brazing;

- lamellar - plates connected by special seals;

- twisted - made of coils, the gaseous substance moves along the bent tubes and the space between them;

- spiral - thin steel plates wrapped in a spiral.

There is a large amount of equipment. But for solving numerous problems it is better to buy a plate heat exchanger . It is suitable for almost all household and industrial appliances.

Range of applications

Heat exchangers are in demand in various fields. So the equipment is used in such industries as:

- food industry - production of sugar, vegetable oil, beer, alcoholic beverages (used for cooling, processing food);

- utilities - hot water supply, water heating, plate elements are used;

- shipbuilding - the engine and the central part of the vessel are cooled by a heat exchanger, here the engine oil or sea water is suitable as a working medium;

- oil and gas processing industry - plate devices are used for heating, cooling, cracking of oil products;

- metallurgy - heat exchangers are used as coolers, spiral, welded, brazed are suitable, the choice of device depends on the operating conditions.

Most plate heat exchangers allow working with aggressive substances under significant pressure. When choosing units, it is important to take into account the scope of their use, technical characteristics.