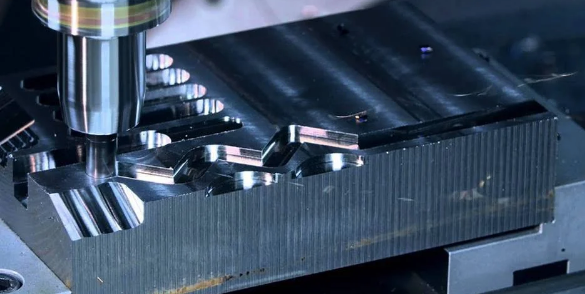

Metal processing demands more and more precision. The use of machine tools under the control of computer programs allows you to perform operations of any complexity without deviating from the specified parameters. CNC metal processing is in demand by industrial enterprises of Belaya Tserkov, as well as other cities of Ukraine and abroad. Its undoubted plus is the ability to integrate with any type of equipment. It is enough to set up a grinding, milling, drilling or lathe once, as well as its variations or modifications, so that later the user can use the algorithm to work with all equipment.

Features of machining using CNC machines

Metal processing on CNC machines is relevant in cases where it is required to manufacture a large number of parts with high accuracy of all parameters. The process is controlled by a computer program, the participation of the operator is necessary only at the time of launch. The machining carried out in this way has become much easier and better. CNC manufacturing of parts allows you to automate the entire production cycle, as well as to use multi-station equipment, increasing the productivity of the enterprise, reducing the time of work, the cost of production. Working in automatic mode allows you to avoid mistakes made by inattention, as well as provide the following advantages:

- excellent quality of finished products;

- desired surface roughness;

- precise dimensions, perfect conformity to the shape of the products.

Thanks to the use of software control, it became possible to manufacture small metal parts without dimensional errors. The use of CNC machines allows:

- Increase the speed of work without losing quality. The operator is required only for setting, starting the machine. Then all operations are carried out automatically, eliminating the need for manual reconfiguration. The machine itself changes tools, combines several operations, which can significantly reduce the time of machining.

- Plan the exact timing of the work. Previously, metalworking was done by hand. Its speed was influenced by many factors, including the experience of the operator. Today, all operations of the same type take the same amount of time, which simplifies planning for mass production.

- High precision. Under the guidance of a computer program, the machine produces exactly the same parts, the difference in dimensions of which does not exceed a micron. The influence of the human factor on the metalworking process is completely excluded.

Using CNC machines allows you to create the most complex parts. Therefore, such equipment is successfully used in the automotive and aircraft industries.

Order metalworking in Ukraine

In Ukraine, there are more than a hundred metalworking workshops throughout the country. Modern Ukrainian metalworking centers offer metalworking services of any complexity. High-precision equipment from leading European manufacturers, highly qualified personnel ensure the ability to fulfill the most complex orders in a short time.

Full automation of processes eliminates the likelihood of marriage. Affordable cost of services, high speed of order fulfillment will be an additional advantage of cooperation.