The technology of creating reinforced concrete structures at a construction site at first glance seems extremely simple. Slab formwork is fixed in position, allowing concrete freeze in the desired position, creating the next floor of the building. The use of disposable formwork significantly increases the cost of work. The use of professional equipment increases labor productivity, significantly affects the speed of building construction and the accuracy of walls and ceilings.

Advantages of precast formwork

The speed of erecting formwork from classic uncut boards, plywood and nails is very low. Builders constantly have to take into account the exact dimensions, the position of individual elements and many other variables. The prefabricated structure consists of many elements, but they are perfectly combined with each other:

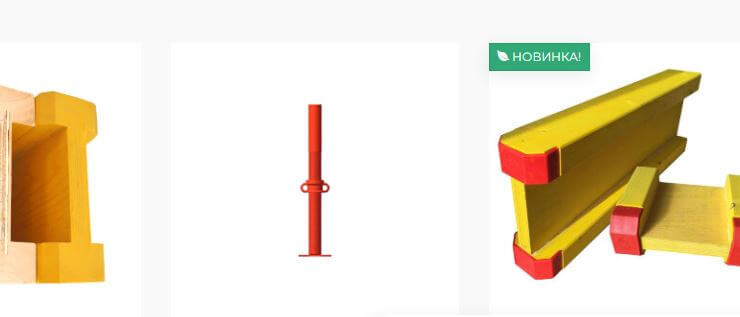

- Metal frame with mounting holes

- Damage-resistant metal or plywood shields.

- Additional steel tubular stops.

- Multiple tie-downs and multifunctional fasteners

- Additional accessories and protection elements.

Smartly designed wall formwork perfectly resists the damaging effects of high humidity. In difficult everyday operating conditions, it is quite capable of withstanding from 80 to 100 cycles of use. Steel or aluminum frames are able to withstand dynamic and static loads up to 300 liquid concrete pouring cycles.

Using formwork in practice

Special construction and installation equipment used at the construction site, first of all, saves time. The designed building can be built in less time, with a better result of the foundation, walls and ceilings. This, in turn, has a positive effect on the life of the entire building as a whole. The main factors of application in practice are worth highlighting:

- reliability of the structure at the time of pouring;

- no leakage of liquid concrete;

- high precision geometry of the final result;

- formwork does not absorb moisture from concrete;

- speed of installation and dismantling at the facility.

In addition, the formwork can be transferred from one level to another on its own, without the use of lifting mechanisms. Individual elements are relatively light, for transportation by workers. Foundation formwork has additional moisture protection from the ground. Keeps its geometry during multiple installation.