According to media reports, the Swiss company Panatere, which processes raw materials and recyclables, has opened two of the world's first solar furnaces for steel processing in La Chaux-de-Fonds, canton of Neuchatel. This project marks an important technological milestone in advancing the production of decarbonized and round steel.

"There is a real interest in recycling our valuable resources. We want to save metal waste from factories and recycle it on site," said Rafael Broye, CEO of Panatere, describing the project as a demonstration of "true environmental sustainability."

Switzerland imports about 140,000 tons of stainless steel annually, including 15,800 tons for the watch industry and 6,500 tons for the medical sector. Panatere's solar energy recycling initiative aims to reduce dependence on imports by recycling local scrap.

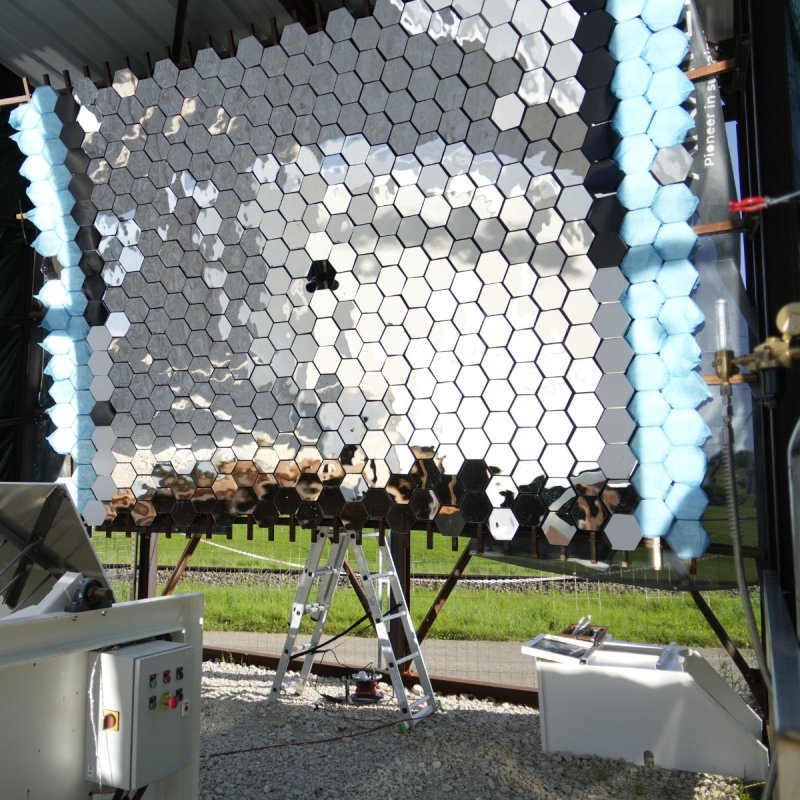

By using 500 concave mirrors and a heliostat to concentrate sunlight, the furnace can heat up to 2000°C, melting metals in just 1.5 hours with zero carbon dioxide emissions.

Panatere's initial goal is to recycle five percent of the domestically produced metals that are currently exported as waste.

By 2028, the solar energy center in La Chaux-de-Fonds plans to produce 1,000 tons of solar steel per year, providing local industries such as watchmaking and medical production. The project is also expected to create new local jobs and boost regional economic activity.

The solar steel project has received broad institutional support, including from the Federal Office for the Environment, the cantons of Neuchatel, Jura and Bern, SIG (Services Industriels de Genève), the Ministry of the Swiss Climate Fund and the Energy Laboratory.

The first solar-powered steel bar will be on display at the International Clock Museum in La Chaux-de-Fonds.

Steelorbis.com