Today, cyberattacks are a daily occurrence, and attacks on technology-oriented industrial enterprises pose a threat to the steel sector as well. In the past, the isolation of OT-Operational Technology networks ensured the security of the enterprise, but thanks to the new technical paradigm and built-in automation systems, cyberisks are growing exponentially.

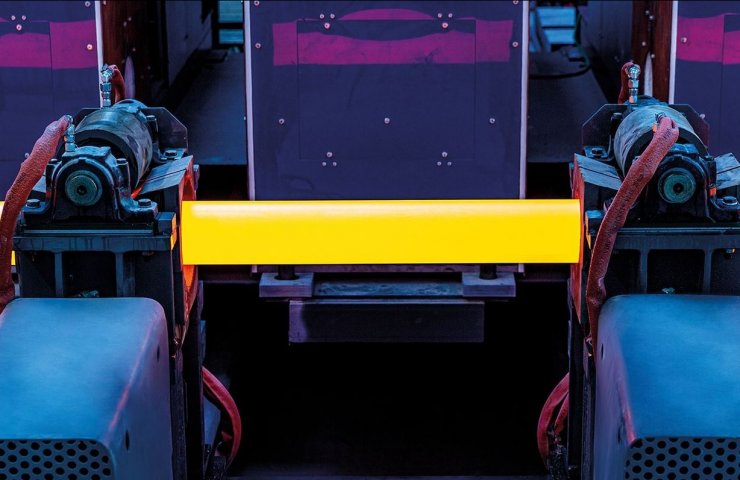

Italian industrial equipment group Danieli has commissioned a new automated wire rod mill at the Acciaierie Bertoli Safau (ABS) mini-mill in the province of Udine in northern Italy.

The new ABS QWR4.0 is a technologically advanced cyber-physical rolling mill installation, so Italian engineers needed to run secure automation systems that were cyber-secure in design.

An advantage of the implemented systems, Danieli Automation called “service continuity” through a highly available, highly virtualized IT environment and remote backup system with geographic redundancy for complete resilience in the event of an attack or natural disaster.

In particular, the physical separation of the LAN between major enterprise systems (eg IT, OT, Voice /CCTV and BMS) has been implemented, and the heavy use of VLANs has been implemented to improve segmentation between access and data flows between systems. It also implemented hardware and software flow control to detect abnormal behavior.

The combination of these effective solutions, according to Danieli Automation, will ensure the continuous and safe operation of the ABS metallurgical plant from hacker attacks. They noted that such systems can be applied to existing installations.

Let us remind you that the new QWR 4.0 rolling mill, currently the only one in the world, allows annually to produce up to 500 thousand tons of high-quality wire rod, including from special steel grades, with a diameter of 5 to 25 mm. The rolling speed is up to 110 meters per second. Service staff - 14 people.