Modern enterprises and facilities associated with the production and use of petroleum products are faced with the need for effective drainage and wastewater treatment. For this, specialized devices are used, such as an oil separator and an oil product separator. These systems help separate oils and petroleum products from water, preventing environmental pollution and ensuring compliance with environmental regulations. In this article, we will look at how these devices work and the benefits they provide.

Oil Separator: Basic Functions and Applications

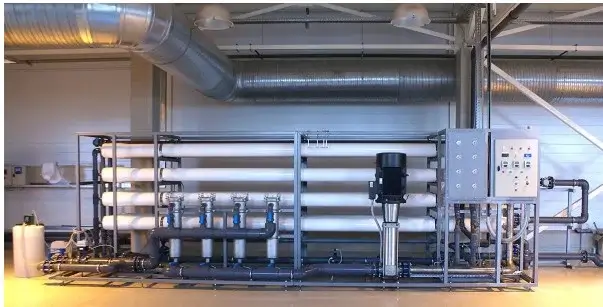

An oil separator is designed to remove oil-containing contaminants from wastewater. Its operating principle is to take advantage of the difference in density between oil and water: the oil rises to the surface and is separated, while purified water is removed from the system. Such devices are widely used in car washes, gas stations, industrial complexes and other facilities where water is contaminated with petroleum products and oils. An oil separator helps reduce environmental pollution and extend the life of the drainage system by preventing clogging of pipes and equipment.

Oil separator: Why is it needed?

Oil separator is a device specially designed for separating and removing oil products from wastewater. Its use is especially important in enterprises where the production process produces wastewater with a high content of petroleum products, such as oil refineries, chemical plants and car service stations. Oil product separators allow you to purify water, minimizing the risk of pollution of water bodies and the environment.

Advantages of using separators

Installing oil and oil product separators has many advantages. First, they help ensure compliance with environmental standards and regulations, which is important for businesses that handle hazardous substances. Secondly, separators help improve the quality of wastewater, which makes it possible for its further purification and use. In addition, the use of such devices extends the service life of drainage systems, as it prevents the accumulation of oils and petroleum products in pipes and equipment.

How to choose a suitable separator?

The choice of a separator depends on the specific operating conditions and site requirements. It is important to take into account the volume of wastewater, the level of pollution and the operating characteristics of the enterprise. Different models of separators have different capacities, which allows you to choose the best option for any type of facility - from small car washes to large industrial complexes.

Thus, wastewater treatment devices, such as an oil separator and an oil product separator, are necessary elements of a modern drainage system. Their use helps reduce environmental risks and ensure efficient operation of the enterprise. Choosing the right equipment and using it correctly is the key to success in cleaning and protecting the environment.