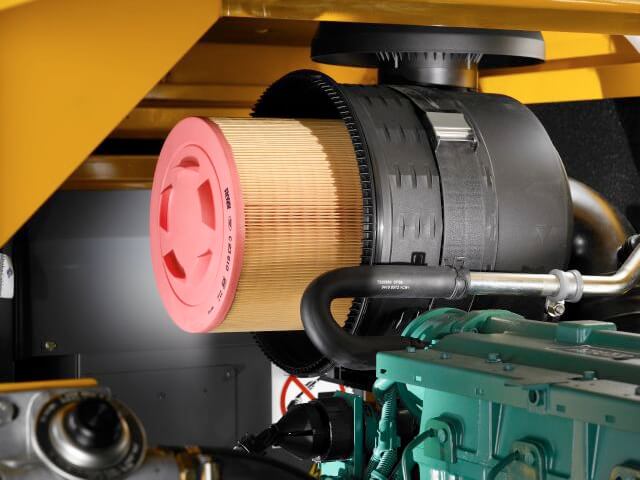

Compressed air is used in many industries. With the help of it, the tool is set in motion, containers are filled, holes are cleaned. But in order for the compressor to work properly for a long time, it is necessary to use high-quality filter elements https://www.compressor-filter.ru/. Properly selected, they will reduce the likelihood of an emergency stop of the compressor, due to premature wear of individual parts.

What air filters affect

Their main role is to prevent dust, dirt and other suspended particles from getting inside the compressor. Getting into mechanically moving parts, they provoke premature wear of compressor equipment. Including valves and other critical parts are taken away with their particles. A properly selected filter extends the life of the following parts: and suction valves, membranes.

Important: insufficiently purified air has an aggressive effect on precise metal parts. A single grain of sand is not capable of causing serious damage, but if dust enters the installation regularly, it is guaranteed to destroy the air compressor. In addition, filters, as consumables, must be changed periodically.

Oil filters in the compressor

Regardless of the design, a lubricant is necessary to reduce friction and protect moving parts from premature wear. An oil filter is necessary both to clean the lubricant circulating inside the unit, and to trap vapors in the air circuit. Properly selected filter elements guarantee minimum wear of the following compressor parts: ;

No filter lasts forever. Depending on the recommendations of the manufacturer of the compressor and filter elements, they must be changed periodically. Only in this case, the filters will be guaranteed to perform all their duties.