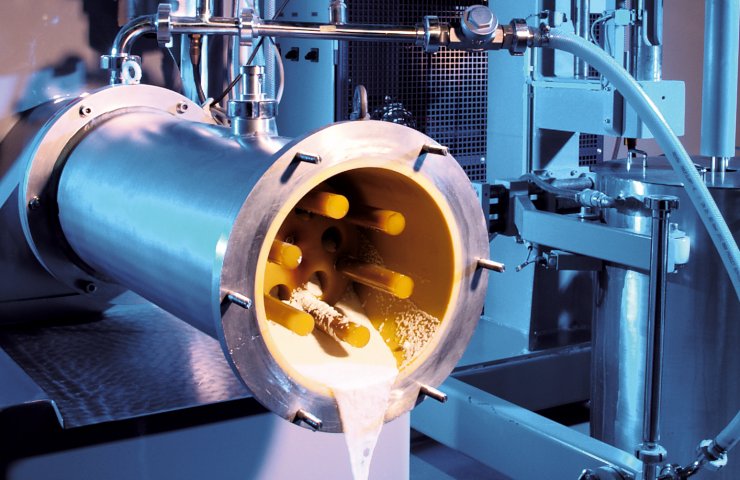

Some types of processes (e.g., metallurgical or chemical sector) require grinding certain enough solid material to a so-called disperse (powdered) state. For this purpose, a specific laboratory equipment, such as bead mills, which, according to the http://www.labotex.ru/, arranged in the following structural scheme:

the

- the

- Rotating vertical mixer (chopper) mounted on a fixed support and connected to the rotor of the electric motor. the

- container, which is the procedure of grinding. Made of highly durable (resistant to abrasion) alloy and has double walls to the cavity between which is filled with coolant.

- the

- In the bowl of the mixer, filled with coolant (usually water) between murine space is the material (substance). the

- In a container is added to the beads of a given strength and diameter. the

- Is start of rotation of the shaft with blades.

- the

- number of fill beads and use the smaller diameter. the

- Intensity of grinding due to the greater speed of rotation of the shaft.

important Enough component to conduct dispersion grinding the beads. Extra durable particles of spherical shape of a given diameter are filled in a container together with the material to be processed.

what is the procedure of grinding

Technological process of grinding of a certain substance to a dispersed state is quite simple. The quality of processing (final crushing) depends on the reliability and technical capabilities of the equipment. So:

the

While a comminuted abrasive substance directly function of the blade shaft, the vessel wall and the bead composition. To improve the grinding parameters or to reduce the duration of the procedure for the odd increasing:

to Get more information about the types and technical parameters of laboratory bead mills using the company website, engaged in their development and production.