The cost of manufacturing metal products is not just the sum of the cost of materials and labor. The final cost is influenced by a whole range of factors: from the complexity of design solutions to the level of technological equipment of the enterprise. Let's take a closer look at what the cost consists of and how to calculate the manufacture of metal structures as accurately as possible.

The design and calculation stage

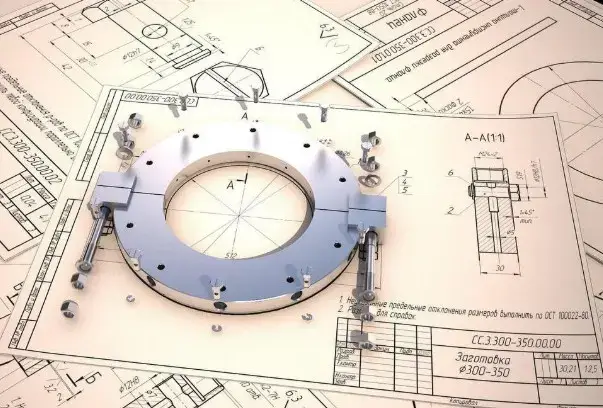

Any production starts with engineering training. At the design stage, specialists create drawings and technical documentation, determine the characteristics of parts and connection methods. Properly designed metal structures can minimize waste and simplify the assembly process.

For large facilities, a price list is often drawn up for the manufacture of metal structures, which indicates approximate prices for materials and operations. The final price is specified after calculating the weight, processing area and complexity of the welded joints.

The main factors influencing the price

To calculate the manufacture of metal structures, it is necessary to take into account a number of key parameters:

- Type and volume of materials. The thickness, grade of steel, and the presence of an anti-corrosion coating directly affect the cost.

- The complexity of operations. The more complex the shape of the parts and the more nodes, the higher the production costs.

- Technological processes. They include metal cutting, bending, drilling, milling, assembly, and industrial welding.

- Surface treatment. For protection and aesthetics, coloring is used, for example, metal powder coating services.

- Installation and transportation. For large products, these costs are also included in the overall estimate.

Contractor's quality and professionalism

The qualifications of engineers and craftsmen, as well as the equipment of the production base, play an important role. The modern plant for the production of metal structures uses automated cutting lines and welding complexes, which ensures stable quality and precision of assembly.

A reliable contractor works strictly according to standards, provides a guarantee for products and accompanies the client from the design stage to installation. This is especially important in the manufacture of custom metal structures, where the requirements for strength and accuracy are as high as possible.

How the final cost is formed

The final price is formed individually for each project and depends on a combination of several factors:

- the volume of the metal and its market value;

- the number of parts and assemblies;

- level