Promising technology is gradually gaining popularity. Relatively new, it has not yet become widespread, but it has all the prospects to conquer the market. High-quality equipment https://aquarezka.ru/ will allow you to achieve a high level of quality in cutting metal blanks, without the need subsequent edge processing.

Machine design features

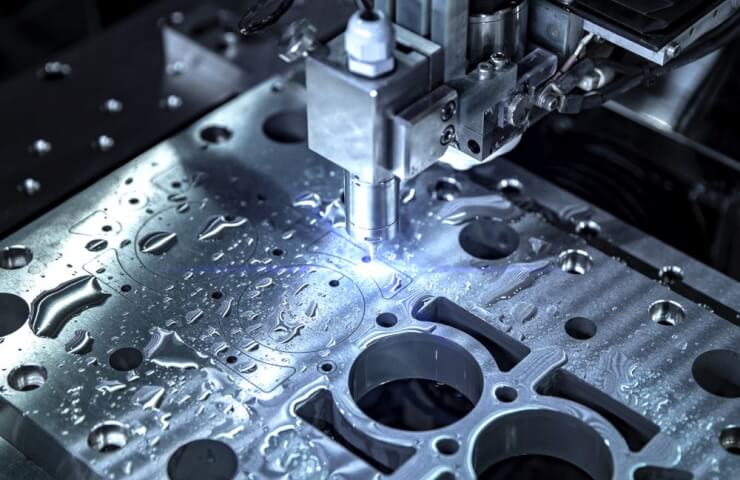

Due to its popularity, metal cutting equipment manufacturers produce both compact models and industrial design machines. The principle of operation in both cases is exactly the same. It all depends on the productivity and ability of the machine to cope with a certain thickness of the metal. The main elements of equipment include:

- Pumping station for liquid supply.

- The coordinate table where the metal blank is located.

- Cutting head that jets liquid.

- A separate system that delivers abrasive to the cutting site.

- Safe machine operator's stand.

Important: Some machine tool builders may install additional items to improve the operator's working conditions or increase productivity. But, in general, the elements described above represent the base, without which it is physically impossible to achieve the operation of the machine.

Waterjet versatility

In fact, the equipment is designed for cutting not only ferrous and non-ferrous metals. Depending on the configuration and individual settings, the machine is able to cut almost any natural and artificial material. Many enterprises buy this type of equipment, or use the services of contractors in order to be able to cut the following materials as accurately as possible:

- all types of steel, cast iron and non-ferrous alloys;

- natural stone and concrete products;

- tiles and other ceramics;

- all types of polymers, including composite ones;

- glass and numerous natural blanks.

The quality of waterjet cutting directly depends on the equipment, individual settings and practical experience of the operator. By manipulating numerous settings, he can achieve high results.