The start of production of any plastic part begins with the creation of tooling – an injection mold, or a matrix. This is the very first and significant investment, which directly affects the cost of future products and the quality of their production. The price of manufacturing matrices for plastic casting can range from several tens of thousands to several million rubles. Such a huge variation is due to a variety of technical and economic factors. Understanding these factors allows you to optimize costs and choose the right contractor for the project.

Fundamental factors shaping the cost of the matrix

The first thing that determines the price is the complexity of the part itself. A simple flat lid will require a shape with a single connector plane, while the device body with many internal ribs, windows and complex surfaces needs a multicomponent design. Such tooling will include a variety of extendable cores, sliders, and inserts, which increases the number of parts, processing complexity, and assembly time. The second key factor is the matrix material. Aluminum or mild steels are often used for small series or prototyping. For large-scale production, where the mold must withstand hundreds of thousands and millions of cycles, high-strength hardened steels are used, which significantly increases the cost of both the workpiece itself and its machining due to the high hardness of the material.

The dimensions of the future product directly affect the size of the mold itself. The larger the part, the more massive and heavier the steel block-billet will be, and the more time it will take for milling, electroerosion treatment and grinding. Accordingly, the material and machine time costs of high-precision equipment are increasing. A separate point is the surface treatment and finishing. Polishing the working cavity of the mold to a mirror-like shine is necessary to obtain glossy surfaces on the parts and make it easier to pull out the product. Texturing or coating to increase wear resistance and corrosion resistance are additional technological operations that affect the final price.

Technological and organizational aspects of pricing

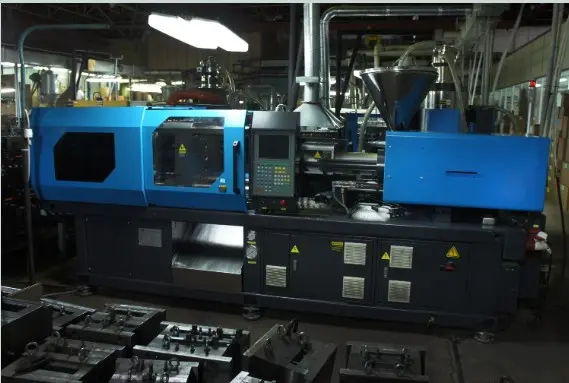

Choosing a tool manufacturer is a balance between price, quality and time. Large specialized enterprises with a fleet of modern equipment, such as CNC machines, wire-cutting and carbon-stitching electric erosion machines, can offer high quality and stability, but their services will cost more due to the high depreciation of equipment and the salary level of qualified engineers and operators. Small workshops or freelancers can