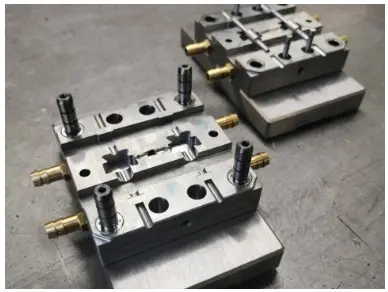

Investments in high—quality tooling are one of the most significant items of expenditure in the production of plastic products. And these investments must be protected. The life of a mold is measured not only in casting cycles, but also in years of uninterrupted operation, and its prolongation directly affects the cost of your products. A key factor in longevity is not only the high—quality manufacture of plastic injection molds, but also proper operation and regular professional maintenance. Neglecting these rules can significantly shorten the life of an expensive instrument, negating all the advantages of the initial investment. In this article, we will look at practical steps that will allow you to maximize the return on your tooling.

Proper operation

The behavior of the operator and adjuster of the injection molding machine (TPA) is the first and main barrier to protecting the mold from premature wear. It all starts with the correct installation. The equipment must be securely fixed to the plates of the machine, without distortion and stress. The use of intermediate plate gaskets is unacceptable, as it leads to uneven loading and can cause deformation. Before starting, always check the operability of all systems: the ease of travel of the ejectors, the presence and correctness of the strapping connection (water supply for cooling, pneumatic cylinders for sliders).

The critical parameter is temperature. Sudden fluctuations are the main enemy of steel. Before starting work, the mold must be heated to operating temperature. Never inject the melt into a cold mold! This causes thermal shock, which can lead to microcracks. Similarly, it is not allowed to cool the mold under the pressure of closed plates — this can lead to its "sticking" and damage during subsequent opening. Compliance with the temperature regime is a simple but extremely effective rule that preserves the structural integrity of the metal for many years. That is why technologists involved in the manufacture of plastic injection molds always attach a passport with recommended temperature conditions.

Regular maintenance

Regular maintenance is not just cleaning, but routine diagnostics that prevents serious breakdowns. After each shift or production cycle, it is necessary to visually inspect and clean the forming cavities. To do this, use only soft materials, such as copper or wooden scrapers, and special cleaning agents. Steel is prone to corrosion, especially when using materials that emit aggressive volatile substances (for example, PVC). After cleaning, all work surfaces,