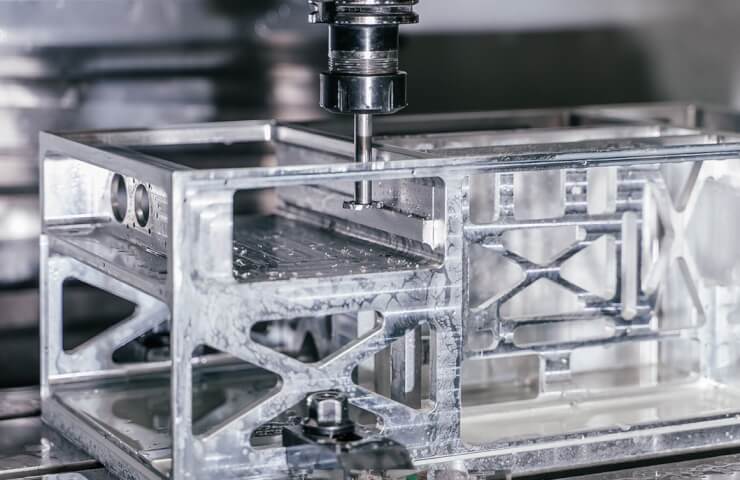

Numerical control machines (CNC) have become an integral part of modern manufacturing. Their use can significantly improve the accuracy and speed of material processing, especially in the field of metalworking. Let's look at how these machines work and what benefits they bring to manufacturing enterprises.

What is the difference between CNC machines and traditional machines?

The main difference between CNC machines is the availability of software that controls the movement of the tool and the workpiece. The programs are created in advance on the computer and loaded directly into the machine. This means that the operator does not have to manually adjust the position of the cutting tool or change the direction of movement.

This ensures high processing accuracy, reduced waste, and significant time savings. CNC machines allow you to create complex shapes and surfaces that are difficult to reproduce manually.

Types of CNC machines

There are several types of CNC machines, each of which is designed for specific tasks.:

- Milling machines are used for cutting planes, forming surfaces and drilling holes. The milling tool moves along three axes of X, Y and Z coordinates, providing maximum processing flexibility.

- Lathes are used to process rotating bodies such as cylinders and cones. The main movement of the tool is carried out around the axis of rotation of the workpiece.

- Multi-axis machines are a special class of machines that combine elements of milling and turning devices. They can process complex geometric shapes simultaneously with several tools.

Advantages of using CNC machines

Let's consider the main advantages of using CNC machines in the metalworking process.:

- High precision - thanks to the software control, precise positioning of the tool relative to the workpiece is ensured.

- Quick tool change - The ability to quickly change tools increases productivity and reduces changeover costs.

- Automation of processes - the absence of the need for constant monitoring by the operator increases overall work efficiency.

- Versatility - a single machine can be used to perform a wide range of tasks, which reduces the need for a large amount of equipment.

Problems and limitations

Despite its many advantages, CNC machines also have their drawbacks.:

- High cost of equipment and the need for regular maintenance.

- The need for special training,