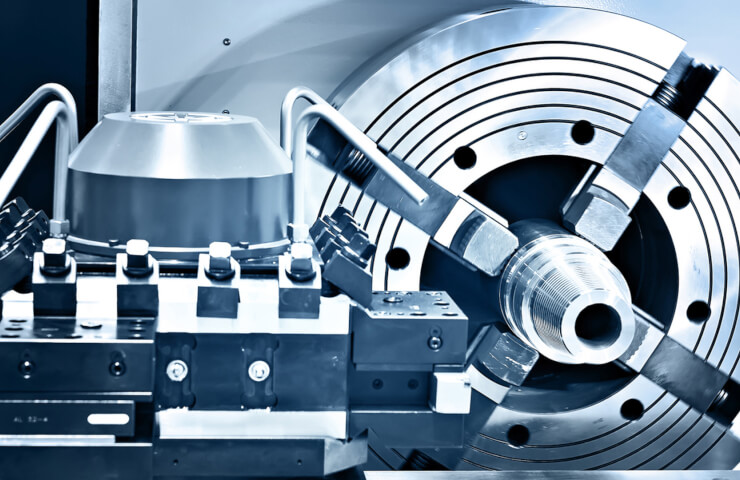

It is difficult to imagine modern industry without the use of lathes of various designs. But, all of them are united by one important detail, the universal lathe chuck https://impulsprom.com.ua/catalog/tokarnyy-patron-200-mm. It can have a variety of diameters, but is designed for one purpose, holding the workpiece in the process of its direct processing.

Chuck selection options for a lathe

The design of the part provides a strong hold on the workpiece at the moment when it rotates at high speed relative to its center of gravity. Strong, hardened steel is always used as a basis, capable of resisting premature wear during operation. But, despite the huge variety, the choice will always be made according to standard rules:

- the maximum allowable outer diameter of the cartridge;

- the number of jaws varies from 2 to 6;

- features of the technical design;

- fitting on the drive shaft of the machine;

- the mounting hole can have a certain diameter.

Do not forget about the diameter and number of mounting holes. A properly selected lathe chuck will ensure trouble-free operation of the device. It guarantees the accuracy of manufactured parts and the absence of increased vibrations, which negatively affect the performance of the machine as a whole.

Classification of lathe chucks

There are a large number of various metal and even polymer blanks that certain machines work with. Strong fastening of the workpiece guarantees its high-quality processing. In this regard, the industry produces a fairly wide variety of chucks:

- The collet chuck provides the fastest possible fixation of the workpiece, but with relatively little effort.

- The lever chuck is applicable for small-scale production of the same type of parts .

- The wedge chuck provides the most accurate positioning of the workpiece.

- Standard jaw chuck, maximum versatility.

The latter are especially popular, both on industrial equipment and in the case of using machine tools in the workshop. Properly selected lathe chuck patrony will last more than one year, will not require repairs. Maintenance consists only in maintaining cleanliness and periodic lubrication of mechanical and moving parts.