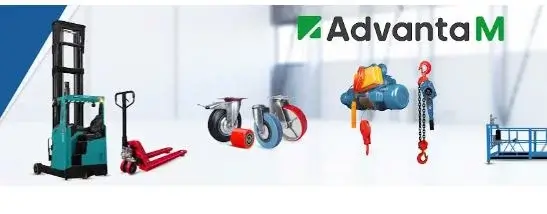

Not a single, even a small warehouse can do without auxiliary mechanisms for lifting and transporting numerous loads. Properly selected mechanical helpers https://spb-advanta.ru/ will ensure fast warehouse operation and minimize the risk of product damage. They will allow more rational use of the entire area of the warehouse.

Load-lifting mechanisms

Most of the loads are too heavy for warehouse workers to carry boxes and individual items without consequences for their health. In addition, modern storage standards suggest using a pallet as a unit of area. In order to organize the movement of goods and lifting them onto metal racks as conveniently as possible, the following devices are needed:

- Classic rokhla on wheels with hydraulic drive.

- A simple, manual stacker with a telescopic mechanism.

- Self-propelled, high performance electric stacker

- Mounting blocks for handling non-standard loads

- Electric or mechanical lifting winch

In each case, the warehouse is equipped with its own necessary lifting mechanisms. Only in this way it is possible to achieve improved operation of the warehouse and the use of all the internal space in the building. Even the most ordinary roller platform greatly facilitates the work of warehouse workers.

Reliability of warehouse assistants

Almost all equipment, to one degree or another, faces difficult everyday operating conditions. Mechanisms and platforms are affected not only by static, but also by dynamic loads. High-quality equipment from trusted manufacturers is designed for most warehouses. Standard characteristics worth highlighting:

- insensitivity to temperature changes;

- ease of maintenance by warehouse workers;

- minimum time to prepare for work;

- the ability to replace worn parts;

- resistance to corrosion due to high humidity.

Quality storage equipment remains operational for several years. Closed hydraulic systems do not need topping up. Leakage occurs only due to extreme wear of sealing materials. Mechanical drives need a minimum amount of lubrication, once or twice a year.