Red fire ant (Solenopsis invicta) and Spider-diver (Argyroneta aquatica) inspired the invention of the private research University to create a new metal that is so water-resistant that may one day lead to the creation of unsinkable ships.

Metal created by using very short flashes of laser etching tiny patterns on its surface, which delayed the air.

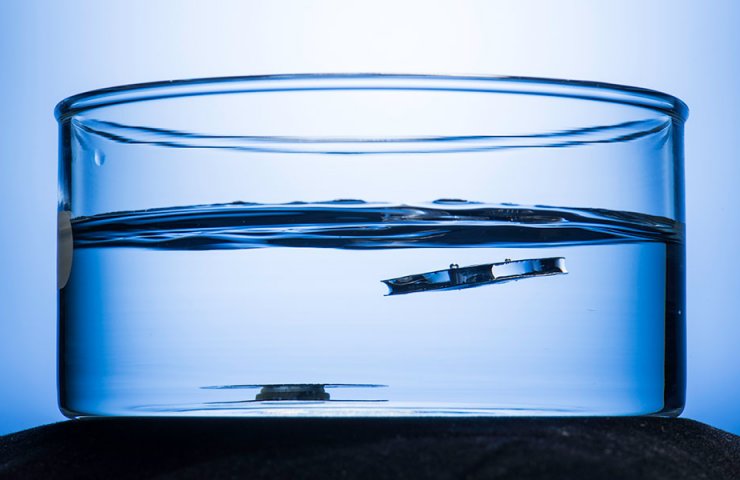

According to the researchers from the University of Rochester, even if the "foam" metal will be under water, he will return to the surface and continue to swim as soon as the excessive pressure is released.

"This could lead to the construction of the unsinkable ship that will still sail after the receipt of the holes, and even electronic devices that can operate in the ocean for a long time," said Professor Chunlei Guo, who led the study.

Fire ants are able to survive over a long period of time under or on the surface of the water, connecting their limbs together, forming a raft. Then they delay the air among their waterproof bodies that keeps them afloat. the Red fire ant is one of the world's most dangerous invasive species of ants have a strong sting and poison that can be deadly for people suffering from allergies.

Spider-diver creates a dome-shaped web, which it fills with air from the surface, and then transfers between water-resistant legs and stomach. The spider uses the air in the dome to breathe, when visiting the surface only when he needs to replenish the supply of oxygen. Spider-water spider, or water spider is a widespread species in Europe spiders of the family Cybaeidae. The only species of spider living in the aquatic environment.

Professor Guo used this method of preserving the air in the bottle to ensure that even after a long stay under water, its metallic design will still hold enough air to be able to swim when you return to the surface.

the Process involves creating two closed on itself, metal surfaces with sufficient space between them to create the air bubble.

the Surface becomes superhydrophobic (extremely water resistant) and can prevent the ingress of water in the Central compartment, even when the design is completely submerged.

Dr. Guo says that "the etching process", which is Central for creating water resistant surfaces can be applied to any metal or alloy.

the Team tested the foamed metal for different periods of time, immersing the sample under water for a long period of time and making sure in maintaining buoyancy. In addition, the researchers inflicted injuries on the metal surface and observed a sample POPs up even when quite extensive damage.