German steelmaker ESF Elbe-Stahlwerke Feralpi will build the most innovative rolling mill in Europe in Riese, northeast Germany, equipped with advanced technology from Italian steelmaker Danieli.

"With all the latest technological advances, this will be the new reference mill for innovation and sustainability," said Danieli.

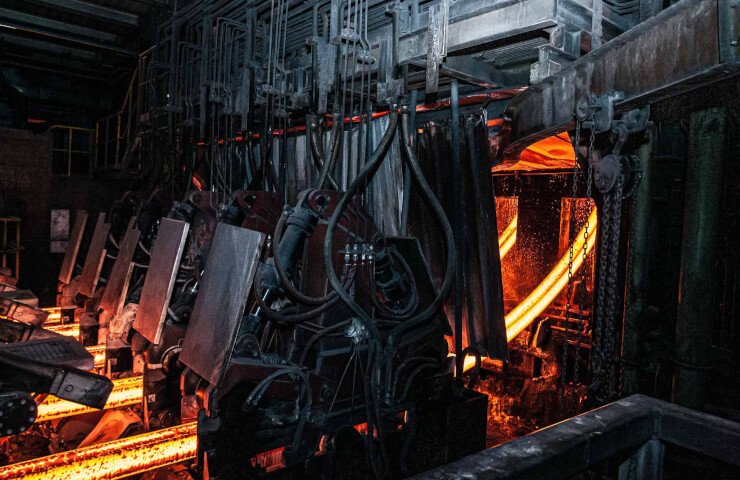

Riesa rolling mill will be connected directly to the existing conticaster using a 300m hot loading roller table to avoid the traditional gas heating furnace, using only induction heating for zero direct CO2 emissions, and a new generation built-in welding machine will be installed to perform infinite rolling.

The mill will consist of 16 frameless rolling stands, a six-pass multi-drive finishing unit and a winding line

It will produce 8 ton coils - the world's heaviest coiled bars for profiles from 8 to 25mm - and Danieli's multi-stage soft-hardening process (SQ2) will provide better and more uniform metallurgical performance.

Daniali Automation big data and artificial intelligence will provide real-time communication between the existing filling machine and the new mill, thereby reducing thermal energy consumption and dynamically adjusting the thermomechanical process to achieve the best end product quality.

The new plant is scheduled to start up in the second quarter of 2024.