The specialists of the metallurgical plant were among the first in the country to start production of high-quality large-tonnage forging ingots due to the transition to a new casting method.

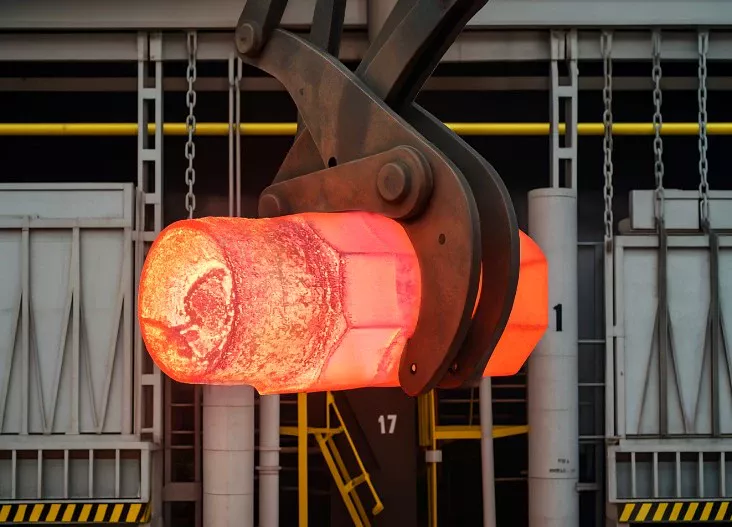

Photo: "Red October".

The technology used allowed not only to improve the quality of the metal surface, but also to expand the plant's offer on the market of forging ingots due to new unique products.

Casting of metal into ingots in the electric steelmaking workshop No. 2 (ESPC-2) since the beginning of the development of their production has been carried out by casting from above in a vacuum, which limited the production capabilities and vintage range in the manufacture of forging ingots.

When siphoning, a different principle is applied: the metal enters the mold from below, passing through a system of siphon wiring – pipes made of refractory bricks. At the same time, argon is supplied to protect the metal jet from secondary oxidation, which also fills the entire volume of the mill, which allows oxygen to be displaced from it.

To introduce the new technology, a special shaped pallet was made in the molding shop, and a number of test steel casts were carried out in the ESPC-2 siphon method.

During further alterations, the 125-ton ingot will be used to make tooling for the stamping press installed at the customer's facility.