Control of maintaining the geometry of various parts is an important process in any modern manufacturing enterprise. As a rule, special equipment is used for this, in particular control and measuring machine. This process is especially important for the metal production industry. What is its importance, and what features can be noted, read on.

Features of the use of control and measuring machines

Thanks to the use of such equipment, the high quality of various parts and workpieces and the entire production process as a whole. When choosing any type of control and measuring equipment, it is important to focus on the goals and objectives and proceed from the scope of application. It is extremely important to pay attention to all the technical characteristics of the measuring equipment - the dimensions of the parts, the speed of the measurement process, the level of accuracy.

When choosing, you should also focus on where the control and measuring machines will be used. This means the installation location is an industrial workshop or laboratory.

The use of specialized devices for quality control of parts makes it possible to automate the measuring process and facilitate all work performed in production. And this, in turn, affects the quality of the final product.

Types of control and measuring equipment

Carrying out linear-angular measurements is a very labor-intensive process and requires a responsible approach . The range of such equipment is represented by the following types of measuring devices:

- Laser scanners.

- Microscopes.

- X-ray units.

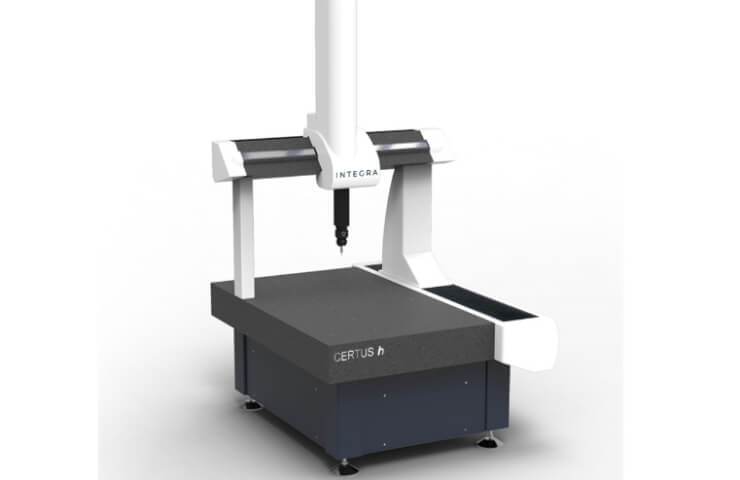

- Measuring machines

- Device for monitoring surface roughness.

- Device for monitoring cylindrical and round shapes.

Measuring machines can have several varieties - coordinator and multisensory. Each of them has its own characteristics and differs in the scope of operation and conditions of use. Therefore, when choosing such equipment, you should proceed from what tasks will be performed with its help.

Thanks to the choice of technical characteristics, scope of operation and features of use, you can choose an instrumentation machine for specific purposes and tasks.